Automatic labelling system to apply two tamper-evident labels on the side corners on the side of formed carton boxes

Pharma Seal has been especially designed to meet the requirements of tamper-evident labelling within operating pharmaceutical packaging lines, by applying two tamper-evident seal labels on formed boxes.

This labelling system has an extremely reduced bulk for a quick and easy installation an integration with other machinery.

Pharma Seal belongs to the Etipack Pharma line, especially dedicated to labelling, coding, serialization and track and trace of pharmaceuticals; this line has been designed to ensure high standards of quality, safety, productivity and maintenance complying with the guidelines for good manufacturing practice of pharmaceutical markets.

The Etipack Pharma line includes different labelling machines, labelling systems and friction feeders to handle a variety of products: ampoules, vials, boxes, syringes, single-dose, inhalers, Blow Fill Seal, inspection and inserting of information notices.

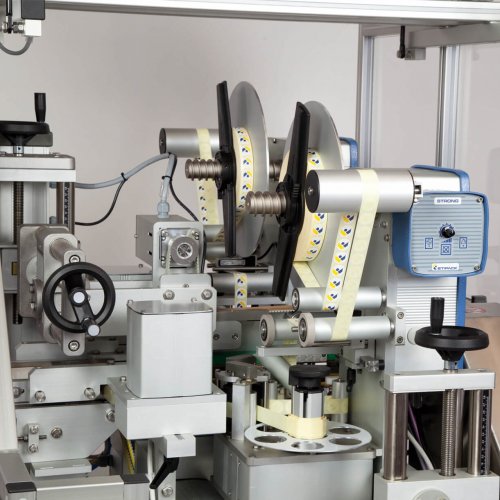

Features of the labelling system

- Varnished steel machine frame with stainless steel panels, Scotch Brite satin finished, with anti-vibration feet, adjustable in height.

- Infeed conveyor to handle the products coming from the line.

- Couple of motorized clamp conveyors to space the products with regulations and scale rulers.

- Couple of parallel toothed belts conveyor with crossover adjustment and synchronous motorization with feedback.

- Two automatic labelling heads for tamper-evident label.

- Device to stabilize the products during the tamper-evident labelling phase.

- Two folding and finishing devices with mechanical adjustment.

- Tamper-evident labelling control by two barriers.

- Air blowing product rejection device with lockable tray.

- Control panel with 3,5″ display, emergency button, multifunctional button (run, stop, reset).

- Pneumatics with air filter assy, pressure regulator, quick discarding electrical valve and pressure switch.

- Failsafe manager software for the peripheral devices diagnosis.

- 3-colour light tower with buzzer to report the running state, alarms and warnings

- Polycarbonate full safety guard.

Ancillary devices

- Maximum loading output signal

- Ultrasound photostop for transparent labels

| Features | |

|---|---|

| Production speed | up to 300 pcs./min |

| Outside reel Ø | ≤ 280 mm |

| Inside reel Ø | 40 ÷ 75 mm |

| Size L - W - H | 1073 x 1436 x 1802 mm |

| Power supply | 230 V, 50÷60 Hz |

| Electrical input | ≤ 1000 W |

| Elettrical protection | IP 54 |

| Noise level | 70 dB |

| Compressed air | 6 bar |

| Tamper evident label size (width x step) | From 20 x 10 to 30 x 30 mm |

| |

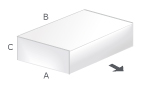

| A_Product size L (min.-max) | 35÷100 mm |

| B_Product size W (min.-max) | 65÷180 mm |

| C_Product size H (min.-max) | 15÷80 mm |