Pharma Flexi is an automatic system for labelling cylindrical products such as vials, bottles, carpules and pharmaceutical syringes.

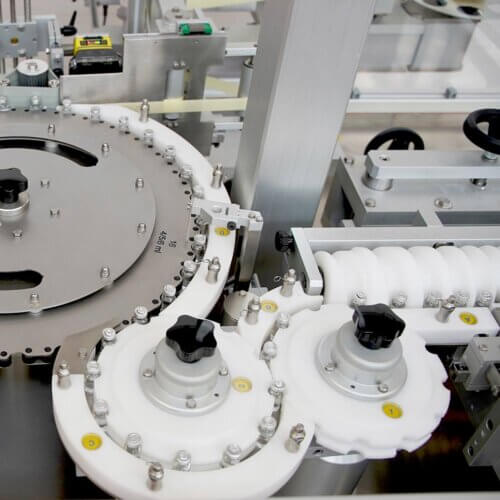

It consists of an infeed belt for product loading, an auger for spacing, a conveying and phasing system to properly hold the product, and a carousel equipped with special housings placed near the labeling station. The label is applied to the product as it passes through, while a rotation device completes the application by rotating the product on itself.

The system can either be used off-line or integrated into the production line. As a matter of fact, the presence of the auger makes it possible to incorporate the system, and by harmonizing the movement of the products, it contains and accompanies them towards the carousel, thus enabling very high labelling speeds to be achieved. The rotary handling system, indeed offers the advantage of being significantly less sensitive to product height, which, even if unstable, will be stabilized.

In a stand-alone version, the Pharma Flexi labeling system is equipped with a low-grip conveyor belt for loading products from manual-loaded tray, and a corresponding unloading trayed system for both compliant and non-compliant products.

The features of the Pharma Flexi pharmaceutical vials and bottles labelling machine

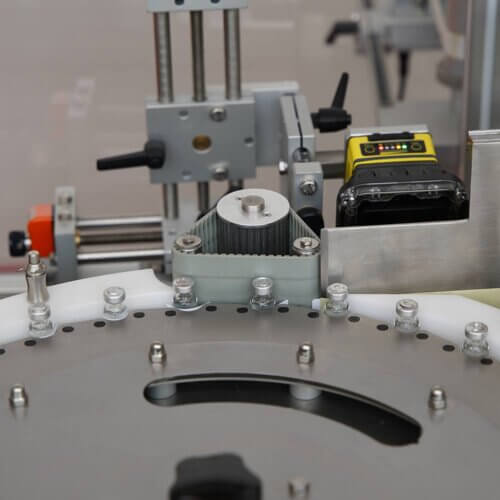

The Pharma Flexi pharmaceutical vials and bottles labeling machine is equipped with an Energy 100 high-production labeler, specific for the pharmaceutical industry, featuring a stepper motor drive with magnetic encoder, which can reach a dispensing speed of up to 400 pcs/min.

The system features an electroluminescence (UV) sensor labeling check station, and can be integrated with a printing unit for overprinting variable data and a vision system for overprinting control.

The Pharma Flexi pharmaceutical vial labeling machine provides advanced reject management thanks to two output carousels complete with a suction system to separate products, and a static tray conveyor for compliant and non-compliant products.

Carousel and guides are changed manually without the use of tools, quickly and easily.

The control panel is integrated into a pivoting mobile arm that allows extensive freedom of movement. Equipped with advanced electronics with Siemens S7 PLC for constant diagnosis of peripherals according to the requirements of the sector, the panel offers the ability to consult wiring diagrams and instruction manuals and to better manage maintenance processes. Designed according to GMP guidelines, it also allows management of FailSafe functions, production batch, and collection of CFR21/Event/Alarm reporting and production data.

This system belongs to the Etipack Pharma line, specially dedicated to labelling, coding, serialization, and track and trace of pharmaceuticals; this line has been designed to ensure high standards of quality, safety, productivity, and maintenance complying with the guidelines for good manufacturing practice of pharmaceutical markets.

The Etipack Pharma line includes different labelling machines, labelling systems, and friction feeders to handle a variety of products: ampoules, vials, boxes, syringes, single-dose, inhalers, Blow Fill Seal, inspection and inserting of information notices.

Technical data

| Features | |

|---|---|

| Production speed* | ≤ 400 pz/min |

| Labeler Model | Special labeler (Kanigen treatment) |

| Size L - W - H | 2740 x 1940 x 2080 mm |

| Product size Ø (min.-max) | 10,75 mm - 25,00 mm |

| |

| Outside reel Ø | ≤ 380 mm |

| Power supply | 230 V, 50 - 60 Hz |

| Electrical input | 1000 W |

Features of the labelling system

- Supporting structure in painted steel, anti-vibration, and adjustable stainless steel support feet.

- Control electronics (PLC SIEMENS S7) in the machine body

- Command and control panel (HMI PC ASEM) on tilting arm, in stainless steel

- PEmergency, reset, stop, run buttons

- Conveyor belt for products feeding with manual unloading tray system

- Minimum input load control.

- Feeding cochlea, with double micro regulation.

- Double input carousel, with quick format change

- Special labeler (Kanigen treatment) for high production dedicated for the pharmaceutical sector, loading, unloading reels and mechanical adjustments external to the guards

- Product rotation device (DRP), to finish the application of the label

- Single UV barrier control (label step ≥ 1/2 product circumference, labels must react to the UV light, not the products)

- Static collection tray loader, for compliant and non-compliant products

- Presence control, maximum tray load

- Air system with disconnector, air switch and main pressure gauge (not lubricated air ≤ 6 bar)

- Aluminum and polycarbonate safety protection

Available ancillary devices

- Format change-overs available with 18, 27 or 36 cavities

- TTO printing unit complete with compensator by micro regulation and position counter

- barcode and/or OCR/V control

- Serialization system

- Ultrasound sensor for transparent labels