Etipack delivers advanced Pharma Labelling in Bonfiglioli Engineering’s 3-in-1 Inspection Monobloc

DOWNLOAD FULL CASE IN PDF

The challenge: integrating labelling into a compact High-Speed Pharma System

A leading Brazilian pharmaceutical company required a compact and fully automated solution for handling an oil-based product in ISO 9187 ampoules. The system had to perform three critical operations: automatic visual inspection of the ampoule tip, leak testing using the pressure decay method, and compliant pharmaceutical labeling at high speed. All in a very limited available space in the facility area where the machine would be installed.

After tailoring its pressure decay leak detection and automatic visual inspection systems to the customer’s production line requirements, Bonfiglioli Engineering collaborated with Etipack to design and integrate a labelling module capable of meeting both performance and requlatory requirements.

The Etipack solution: Compact, Compliant, High-Speed Labelling

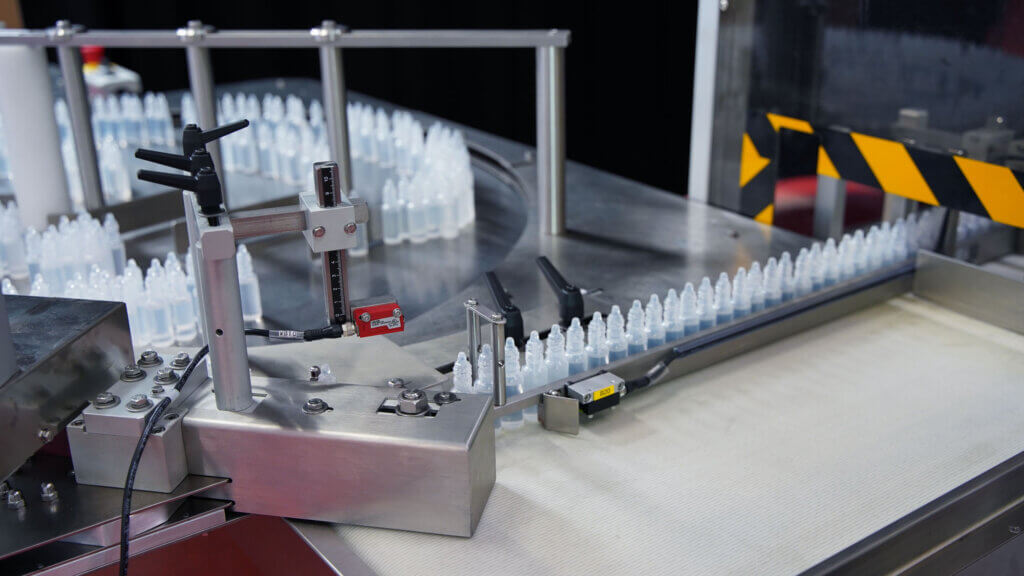

Etipack engineered a dedicated pharmaceutical labeling station to fit seamlessly into Bonfiglioli Engineering’s 3-in-1 inspection monobloc. The unit was developed to operate at 24,000 ampoules/hour, ensuring accuracy, traceability, and full compliance with international pharma standards.

Key Features of the Etipack Labelling module:

- Wrap-around application of self-adhesive labels on 1–20 ml ampoules

- Integrated printer for variable data and QR (pharma) code

- Vision systems for real-time label inspection and verification

- Automatic reject station for non-compliant items

This labeling module contributed to creating a fully automated, GMP-compliant solution for automatic visual inspection, leak detection, and labeling within a single compact footprint.

The results: higher efficiency, smaller footprint

Thanks to the close collaboration between Bonfiglioli Engineering and Etipack, the customer now runs:

- 24,000 ampoules/hour with just 2 operators

- 1 machine instead of 3 separate systems

- Full serialization and visual control integrated in-line

The Etipack labeling unit played a key role in ensuring process continuity, reducing downtime, and meeting the pharmaceutical industry’s strict compliance standards, all within the compact layout defined by the customer.

A strong Partnership for Pharma innovation

This project is a prime example of Etipack’s ability to work alongside leading technology providers to deliver complete, reliable, and scalable solutions for pharmaceutical packaging lines.

Looking for a Pharma labelling solution that integrates seamlessly into your process?

Whether you need wrap-around labelling, quality control, or serialization, our systems are modular, scalable, and ready for seamless integration into the most complex pharmaceutical lines backed by decades of industry experience.

To discover more about Bonfiglioli Engineering’s reliable, high-quality inspection solutions for the pharmaceutical industry read the original case study by Bonfiglioli Engineering here