Wrap-around labelling for buckets of catering sauces

DOWNLOAD FULL CASE IN PDF

Multi-format food container wrap-around labelling system for industrial food service

In the professional food sector, where order and traceability are essential, labelling is a strategic element of the production process. In the food service sector in particular, the correct application of labels on large packages, such as pails and jerry cans, ensures effective management of logistics flows and product information.

Etipack has designed an automated, customised solution for the semi-wrap labelling of multi-format containers for industrial catering. The system is engineered to ensure maximum reliability, even in the presence of critical elements such as handles, and to adapt quickly to format changes, helping to improve productivity and reduce error margins.

A project that focuses on functionality, responding to the concrete needs of food companies engaged in large-scale distribution.

The challenge: effectively labelling containers in different formats, managing handle presence and label orientation

The customer – a subsidiary of a US company that is one of the largest suppliers to the Quick Service Restaurant and retail industries – was looking for a solution to be able to label two types of product with a single system:

- Cylindrical buckets with handle (ø 151 to 284 mm, height 160 to 330 mm)

- Rectangular jerry cans (250x220x250 mm)

The main critical issue was the handling of the handle, which interfered with the application surface, requiring a precise orientation system that could be adapted to different formats.

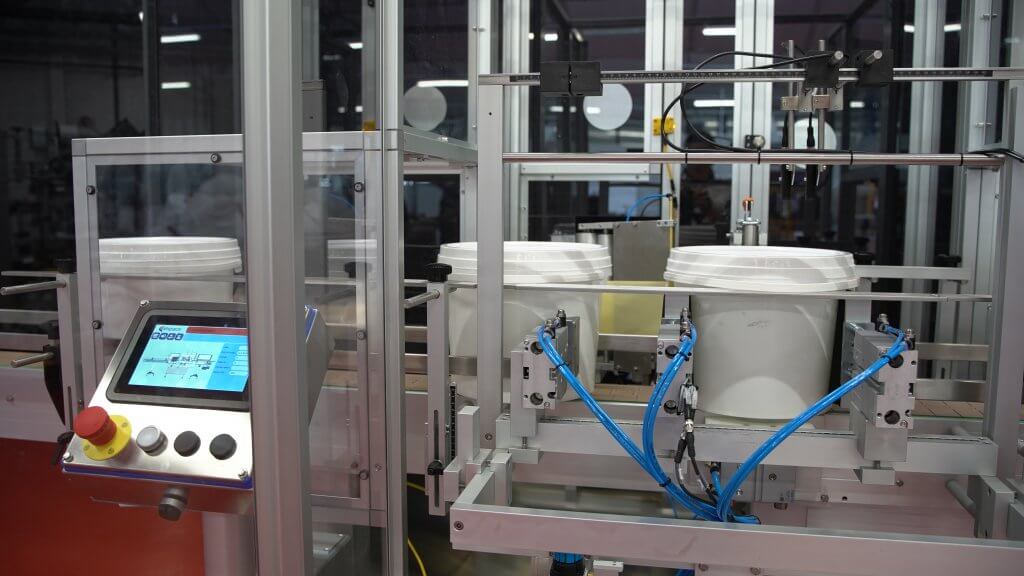

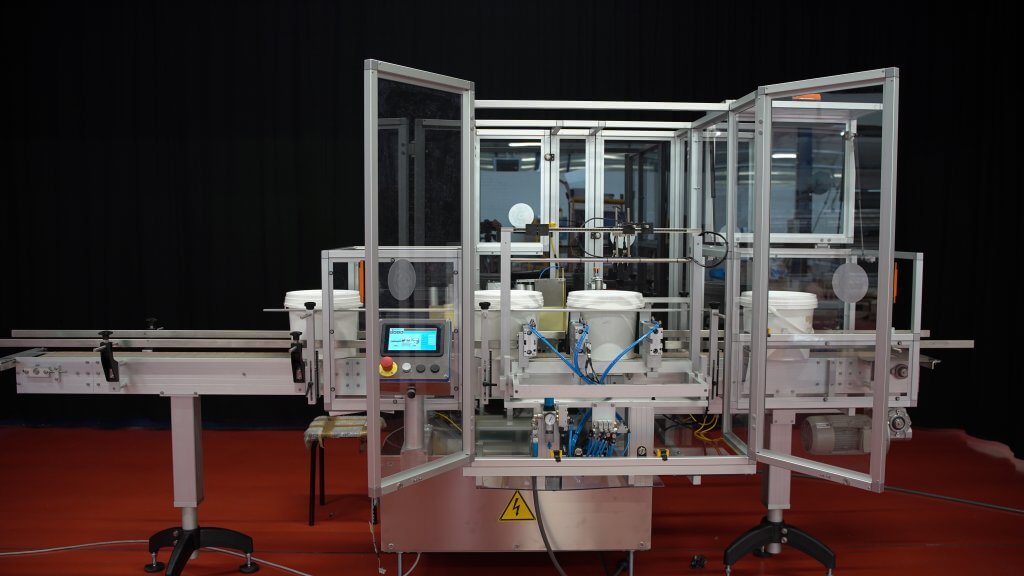

The solution: System 1 Turning with support bar and roller system for applying the label in position

- Customized guides for automatic handle lifting

- Turning orientation device with motorised roller and opposing free rollers to hold and turn the container during application

- Energy 200 automatic labeller with stop photocell for correct label positioning

- Customised pad for the controlled aspiration and release of the label

- Tastex photocell for product presence detection

- Variable speed transport system, capable of handling full containers up to 13 kg

An operator supervises the initial phase to ensure correct positioning of the product with respect to the guide. The system handles up to 6 different formats with simplified format changeover.

User interface

The system is controlled by a 7″ touchscreen display panel (1024×600 resolution), which offers an intuitive graphic interface and advanced customisation features to simplify management and enhance the operator experience

The results: precision application and perfect handling of handle products

The solution, which is ideal for the production of food containers that need special attention due to the presence of handles and require precision in application, ensured:

- Precise labelling even with the handle

- Flexibility in format change

- Increased operational efficiency and consistent quality

The system proved ideal for labelling food containers for the industrial sector.