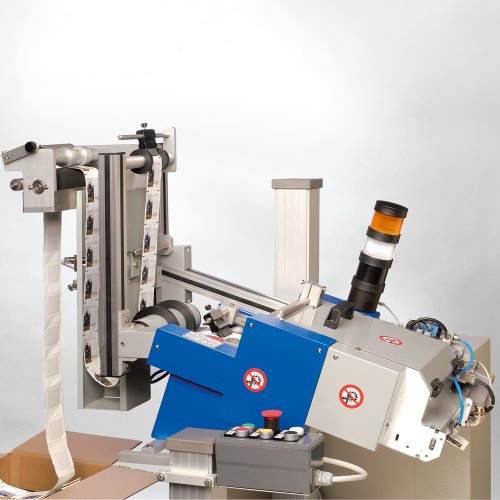

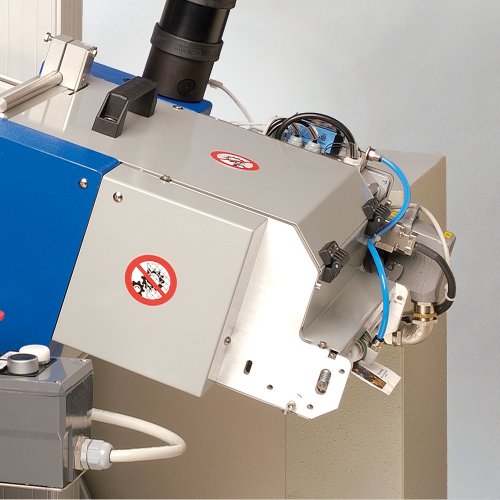

Roll friction feeder

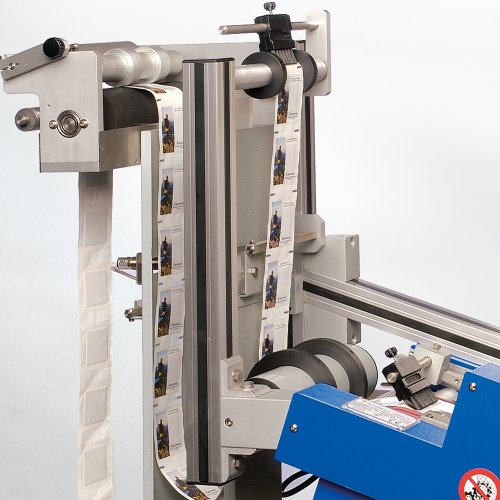

The roll friction feeder Whizzy Roll is an automatic friction feeder specifically designed to feed coupons, backer cards, etc., from a roll format and to cut them to proper size.

The roll feeder provides for full automatic unrolling, cutting and feeding into the pakaging line with a speed up to 150 pcs/min. of different materials with a thickness up to 2 mm, such as paper, cartons, flexible packaging, plastic packaging materials, cleaning pads, food absorbent pads.

The machine is equipped with an orbiter cutter ensuring a clean and precise cut to proper size.

Cutting size is operated from a keyboard by setting length paraments, in order to vary pitch length according to actual manufacturing needs.

Features of the feeder

- Feeding from roll format

- Mechanic unwinder

- Brushless drawing with step movement by stop control

- Orbiter cutter with saw-toothed and brushless motor actioning

- Stop sensor on product distribution

- Separate control box (remote terminal up to 3 m) with integrated PLC

- Separate control panel (remote up to 3 m)

- Brushless motor

- Programming keyboard

Ancillary devices

- Base support structure

- Customized support structure

| Features | |

|---|---|

| Dispensing speed | ≤ 60 m/min (150 pcs/min depending on the products step) |

| Dim. prod. lunghezza | 55 - 300 mm |

| Product sizes L | 50 - 150 mm |

| Product sizes W | 1÷2 mm |

| Product dispensing | Horizontally |

| Dispensing unit width | 366 mm |

| Motor type | Brushless |

| Size L - W - H | 877x672x500mm |

| C.B. dimensions L - W - H | 600x200x600mm |

| Power supply | 230 V, 50-60 Hz |

| Electrical input | 920 W |

| Electric protection | IP 54 |