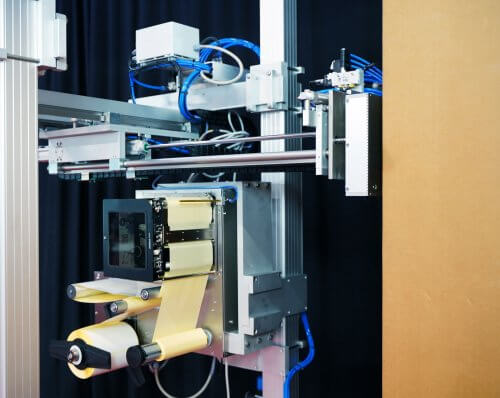

Print and apply machine that applies the last printed label on products at a standstill

Intouch Evo is an automatic Print and Apply system applying the last printed label on boxes and products at a standstill.

Intouch prints any type of code, images, and variable data coming from the packaging line and applies the last printed label.

This Print and Apply model is the most performant of our range thanks to its advanced electronics and application pad. The control panel provides easy interfacing of the machine with different signals coming from packaging lines, while the pad with a 350 mm stroke automatically detects the distance of the application surface and adapts it accordingly.

The core of the Intouch Print and Apply system is an industrial thermal transfer printer with dual processor electronics and equipped with an air jet application pad applying the label on products at a standstill.

Intouch Evo is available in 2 versions: Intouch Evo 4 has a 4″ width and Intouch 6 with a 6″ width.

This Print and Apply machine works with reels of thermal transfer ribbon 600 m long, in order to ensure high autonomy in working cycles.

Resolution 12 dots/mm

Maximum printing speed 300 mm/s

Maximum Label width 104 mm (Intouch Evo 4) and 170 mm (Intouch Evo 6)

Technical Specifications

| Features | INTOUCH EVO 4 | INTOUCH EVO 6 |

|---|---|---|

| Print speed | max 300 mm/s | max 300 mm/s |

| Dispensing speed | ≤ 15 pcs/min | ≤ 15 pcs/min |

| Label size (width x step) | From 50x50 mm to 120x150 mm | From 50x50 mm to 170x210 mm |

| Print area | ≤ 104x150 mm | ≤ 150x210 mm |

| Type of printing | Thermal transfer or direct thermal | Thermal transfer or direct thermal |

| Outside reel Ø | ≤ 280 mm | ≤ 280 mm |

| Inside reel Ø | 40÷75 mm | 40÷75 mm |

| Power supply | 115/230 V, 50/60 Hz | 115/230 V, 50/60 Hz |

| Compressed air | 6 bar | 6 bar |

| Barcodes | All types | All types |

| Text rotation | 4 directions | 4 directions |

• Drawing unit 120 mm (170 mm with the 6″ version)

• Printhead with historical control 8 dot/mm

• Interfaces RS232, LAN Ethernet

• Display keyboard for machine configuration

• Inner rewinder for liner paper

• Inner clock for date/time

• Ethernet cable

• Windows driver

• Balancing/dumping pad, stroke 350 mm

• Control of label presence on pad

• Electric panel board

• Air unit treatment

Ancillary devices

• Start/stop label

• Start photocell

• PC

• Programs for label layout

• Cables

• Interfaces

• Control applied label

• Base and support structure

• U-shaped support structure

• Safety protections