The Etifiale Pro System is an automatic system for the labelling of pharmaceutical ampoules, which are manually loaded with a dedicated tray and then conveyed and channelled towards a carousel, equipped with special housings, up to the labelling station.

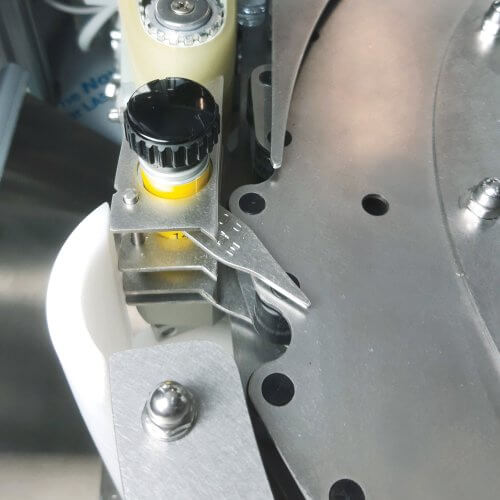

The label is applied to the product as it passes through, thanks to a special retractable blade that ensures maximum precision, and with the support of a rotating device that completes the application by rotating the ampoule on itself.

Features of the pharmaceutical ampoules labeller Etifiale Pro

The pharmaceutical ampoules labeller Etifiale Pro is equipped with a high-production Energy 100 labeller specific for the pharmaceutical sector, featuring a retrofitted stepper motor with magnetic encoder, which reaches a distribution speed up to 60 m/min.

The system features a UV barrier labelling control station, and can be integrated with a printing unit for overprinting variable data, and a vision system to control overprinting.

The Etifiale Pro labelling machine for pharmaceutical vials guarantees an advanced waste management thanks to an ejection device for unsuitable products, which are conveyed into an extractable drawer, and a control device which certifies that the product has been discarded.

The format change to adjust carousel and guides to a different size of ampoules is operated manually in a quick and simple way, without the aid of any tools.

The control panel is integrated upon an innovative mobile pivoting arm that allows wide freedom of movement. Equipped with advanced electronics with Siemens S7 PLC for the constant diagnosis of the peripherals according to the requirements of the sector, the panel can access the wiring diagrams and the instruction manual, allowing to manage the maintenance processes at best. Designed according to GMP guidelines, it also allows the management of FailSafe functions, production batch and the acquisition of CFR21/Events/Alarms reports and production data.

This system belongs to the Etipack Pharma line, especially dedicated to labelling, coding, serialization and track and trace of pharmaceuticals; this line has been designed to ensure high standards of quality, safety, productivity and maintenance complying with the guidelines for good manufacturing practice of pharmaceutical markets.

The Etipack Pharma line includes different labelling machines, labelling systems and friction feeders to handle a variety of products: ampoules, vials, boxes, syringes, single-dose, inhalers, Blow Fill Seal, inspection and inserting of information notices.

Technical data

| Features | |

|---|---|

| Production speed* | ≤ 12.000 pcs/h with Ø 10,00÷12,75 mm |

| ≤ 9.000 pcs/h with Ø 14,25÷17,00 mm | |

| ≤ 6.000 pcs/h with Ø 17,00÷22,00 mm | |

| Size L - W - H | 2301 x 1910 x 2310 mm |

| Power supply | 230 V, 50/60 Hz, |

| Electrical input | ≤ 2300 W |

| Elettrical protection | IP 54 |

| Noise level | 75 dB |

| Compressed air | 6 bar |

| |

| A_Product size Ø (min.-max) | 10÷22 mm |

| B_Product size h (min.-max) | 25÷90 mm |

| * The eventual print unit model could impact on the production rate, to ask to Etipack. |

|

Features of the labelling system

- Machine structure in painted steel with AISI 304 panels

- Automatic loading system for ampoules from drawer via stainless steel plate and conveyor belt

- Conveyor of ampoules to star wheel with independent motor

- minimum loading control

- Tray-loader for outcoming good products with maximum load and tray presence control

- Rotating star wheel for ampoules, with independent motor with inverter

- Self-recognition of the format of the star wheel

- Automatic labelling machines with hybrid stepper motor with magnetic encoder

- Touch screen display for setting and managing more than 50 customized parameters

- Automatic vertical adjustment, with self-positioning after reel change

- Inner capacitive sensor for end-of-reel control

- Tunnel safety protection on the conveyor belt

- Terminal bar for correct application point in carousel

- Product rotation system with independent motor for label application to the rotating ampoule

- Label presence control on ampoules with UV barrier or cameras

- Pushing device of conforming labelled ampoule to collecting tray

- Pneumatic ejection with mechanic extraction of ampoules and gravity fall into tray

- Photocell for ejection control

- Removable tray of rejected ampoules

- Maximum load of ejection tray

- Setting parameters for stops after consecutive rejects

- Advanced electronics with PLC SIEMENS S7

- Energy-saving function to shut down the system in case of inactivity

Available ancillary devices

- Format change-overs available with 18, 27 or 36 cavities

- Choice of different printing units (thermal inkjet, thermal transfer, hot foil)

- Print control OCV/OCR control

- Barcode control

- Serialization system

- Ultrasound sensor for transparent labels