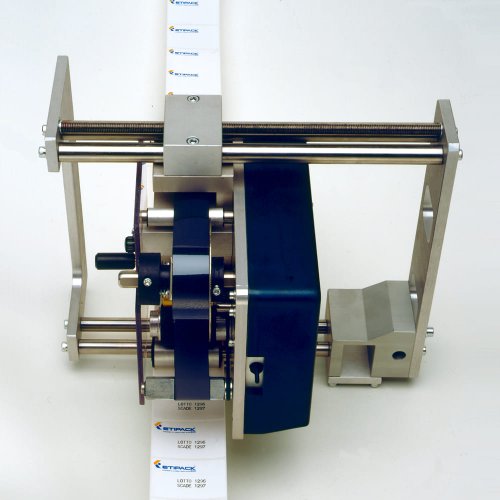

Industrial OEM Print Module to be integrated into various Print & Apply Solutions.

As an engineering company or system integrator, you know your customers expect you to provide complete labeling devices tailored to their requirements. The Print Engine Module (XPM) provides precise, safe printing and labeling for industries such as food, chemical, and pharmaceutical and integrates seamlessly into most production lines, in all Print & Application machines manufactured by Etipack and others.

Extremely high printing speed makes it suitable for the identification of rapidly- moving products at variable conveyor speeds.

Efficient Batch Printing

- Printed labels are forwarded in a loop for further

processing in a labeling machine or a rewinder - Definitive solution for variable product labeling at high dispensing speed

Customizable Production Line Labeling

- Can adapt to production line speed in various industry environments

- Ideal for the food or pharmaceutical industry and where print speed is independent of the dispensing process

Economic Solution

- Increased uptime using 1000m ribbon rolls

- Ribbon save function reduces consumable costs.

Technical specifications

| Features | |

|---|---|

| Printing Type | Thermal transfer/thermal direct |

| Print Speed | Print speed of up to 16” per second (400 mm/s) as a function of print width from 4” to 16 “ |

| Print Width L-w | 4”: 106mm, 5”: 127mm, 6”: 160mm (a 300 dpi) |

| Printhead | 300 dpi |

| Graphic Formats | BMP, PCX, JPG, TIF, GIF, Easy Plug logos |

| Barcodes | all available |

| Display | Five-key control panel with illuminated graphical display; 128×32 dots, with two lines of 16 characters |

| Label Types | All common converted, self-adhesive label material with liner, on rolls. Suitable for printing in thermal direct or thermal transfer process. |