Labelling system for sanitizing gel refill bags

DOWNLOAD CASE IN PDF

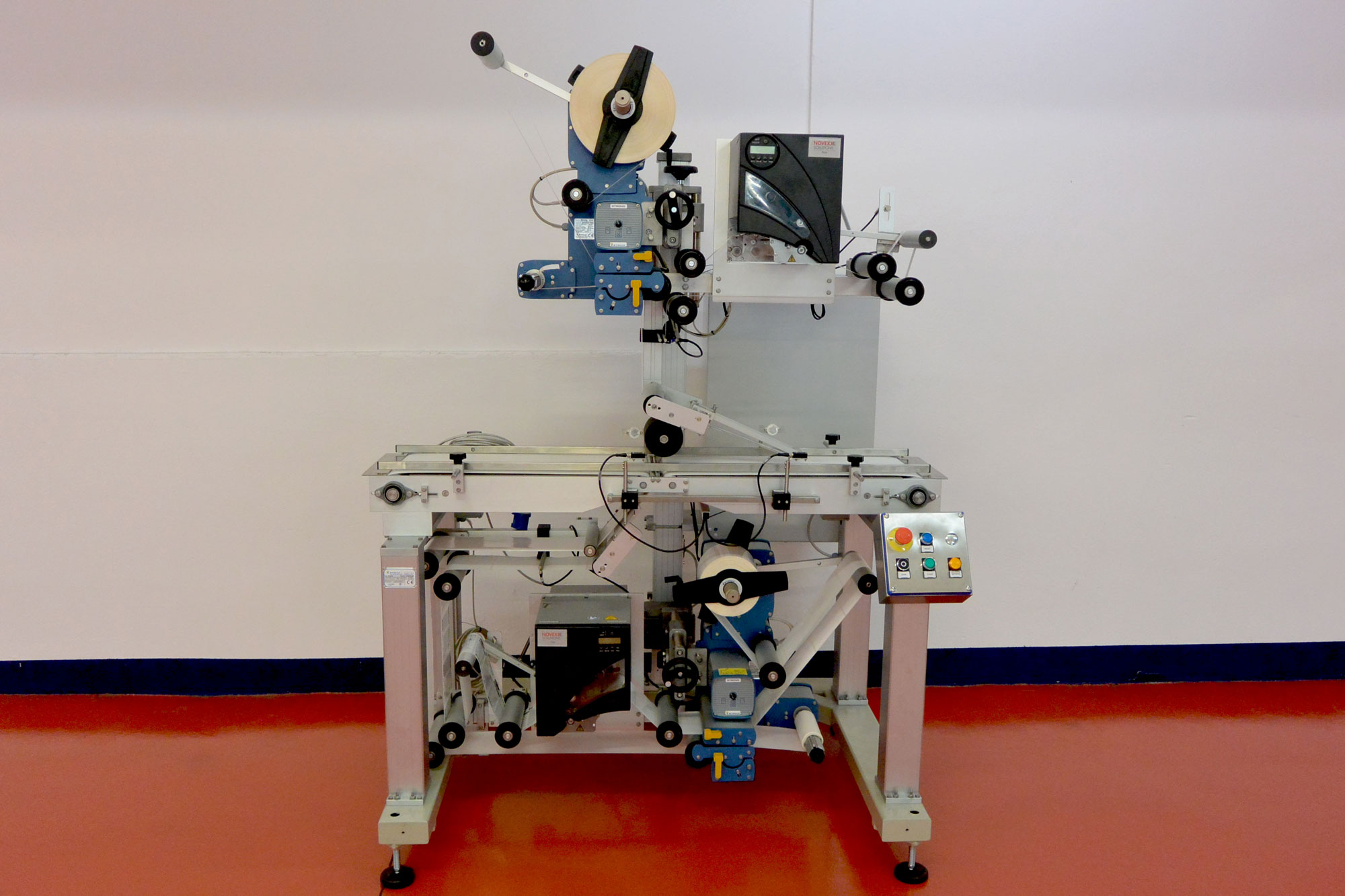

Custom labeling system for applying top and bottom labels to hand sanitizing gel pouches

A U.S. company leader in cleaning, disinfection, and hygiene solutions – for the hospitality, food and beverage, retail, hospital, and janitorial industries – was looking for a system to apply a top label and a bottom label on refill packs of hand sanitizing gel. The need was, in particular, to apply two different label formats on a product characterized by a soft and transparent surface, and to print graphic and variables data on the surface of the labels, before application.

The solution: Custom 4/2 system equipped with two Strong 200 labellers and two print units for graphic layout and variable data printing

In order to achieve this goal, Etipack designed a special 4/2 System, capable of allowing the above and below the application of labels in two formats on the product, integrating two thermal printing modules for label overprinting.

Perfect application on an irregular product

A major challenge was to design the system in order to achieve a high-quality application on a product with particularly complex characteristics to manage: uneven surface, instability, soft surface, and transparency.

System features and configurations

- 2 Strong 200 labellers Eqiupped with stepper motor, they apply labels with an application speed of up to 20 m/min. They are equipped with a belt rewinder, for the recovery of backing paper up to 180 mm in diameter, and with an internal capacitive sensor for end-of-reel control. The upper labeller is equipped with an adjustable long dispensing terminal for a 20 x 40 mm label separation from the backing paper and its application on the product.

- Start Sensors They enable accurate and reliable detection of transparent packaging

- Roller Applicator It acts on the irregular surface of the product facilitating the label application

- 2 PEM Novexx 6″ Print Units They cover a printing width of up to 160 mm with a resolution of 12 dots/mm (300 dpi) and are equipped with a “ribbon saving” mechanism. The upper printing unit is dedicated to variable data overprinting on the smaller label. The lower unit, is programmed to perform the graphic layout printing, together with the printing of variable data.