03/12/2025

Wrap-around labeling system for paint buckets

11/06/2021

DOWNLOAD CASE IN PDF

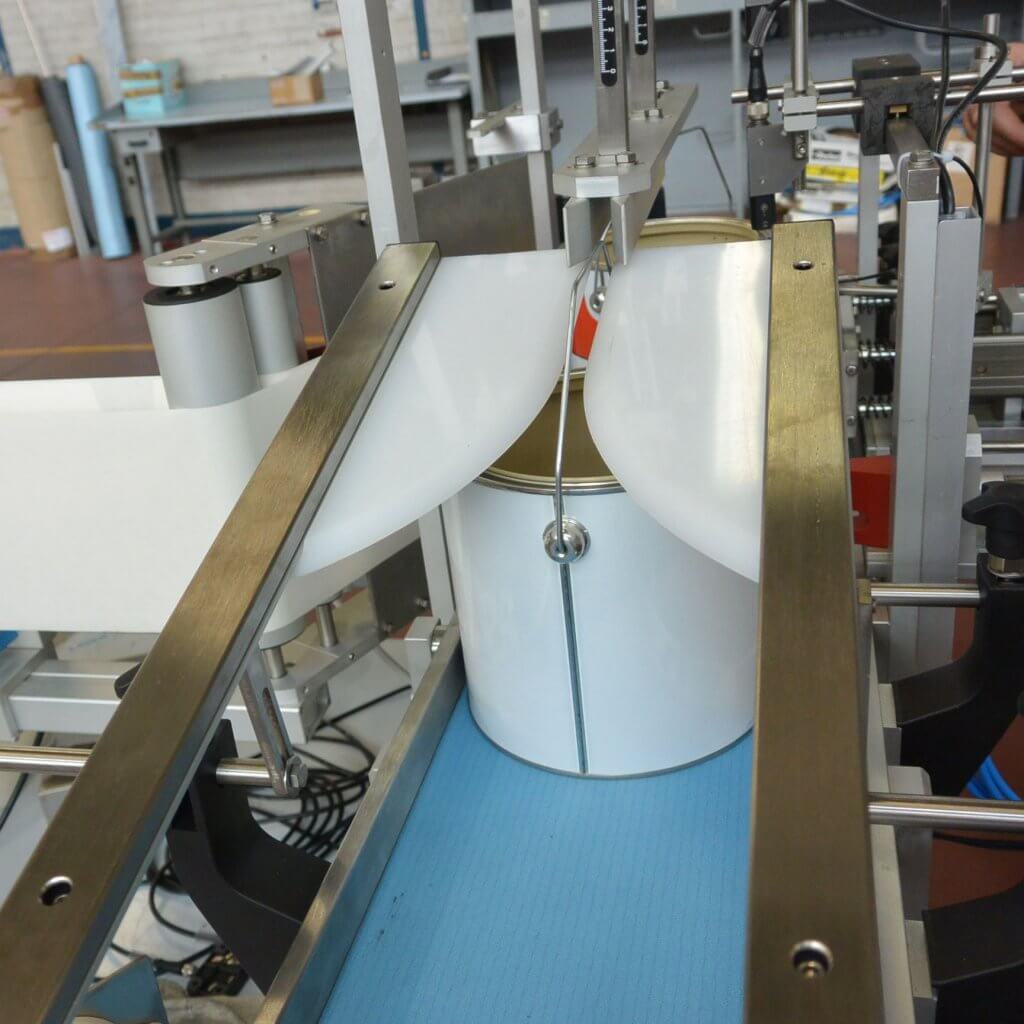

Custom labeling system for wrap-around application of labels on cylindrical paint buckets with handle

Dutch company producing a wide range of paints for the professional and high-end consumer markets was looking for a system to apply large labels to cylindrical buckets of paint. The need was, in particular, to ensure that the labels could be oriented to obtain a precise centering with respect to the handle positioning.

The solution: System 1 Turning with Energy labeller 200 for applying labels of different formats, aligned in relation to the handle

In order to achieve this objective, Etipack designed a special System 1 Turning able to feed the product and orient it in the correct position to allow the application of the label with a precise centering with the handle.

Caratteristiche e configurazioni del sistema

- Labeling machine Energy 200 With a hybrid stepper motor and magnetic encoder, it applies labels at a speed of up to 50 m/min. It features an unwinder with adjustable plate brake and aluminium plates for label reels up to 380 mm in diameter.

- Swinging arm and winding device A swinging arm, positioned before the drive unit, keeps a steady label roll tension. The winder allows empty liners with a diameter of up to 280 mm (380 mm as the diameter of the label roll) to be rewrapped. The internal capacitive encoder detects the end of the label roll.

- Fotocellula Tastex In synchronization with the labeler, it detects the passage of the product and triggers the label distribution

- Control Panel touch screen interface display 2,8”

- Input product orientation Thanks to a customized pre-orientation bucket system, the product is correctly positioned. A special guide then allows the handle to be lifted to enable wrap-around labeling.

- Product orientation for labeling In order to allow the correct application of the label, a turning orientation device has been designed. It consists of two opposing rollers – one to stop the incoming product and the second to position the product to be labeled – and a geared roller spinning the product during labeling. A special magnetic device ensures the handle to be kept raised during rotation. The presence of a photocell allows the label to be correctly oriented in relation to the product.

Latest news