Wrap-around labelling on cosmetics cylindrical jars and bottles

DOWNLOAD CASE IN PDF

Automatic application system for self-adhesive and decorative oriented labels on cylindrical cosmetic products such as jars or bottles

Application perfection is a must for consumer products in beauty and cosmetics markets: products for the shelves need to be eye-catching to encourage choice.

A contractor specialized in the cosmetics industry that manufactures for large international companies needed to apply labels with a high degree of precision and faultless such as air bubbles or ripples. In addition to accuracy, a second need was to orient the labels with respect to a well-defined point on the cylindrical jars or bottles.

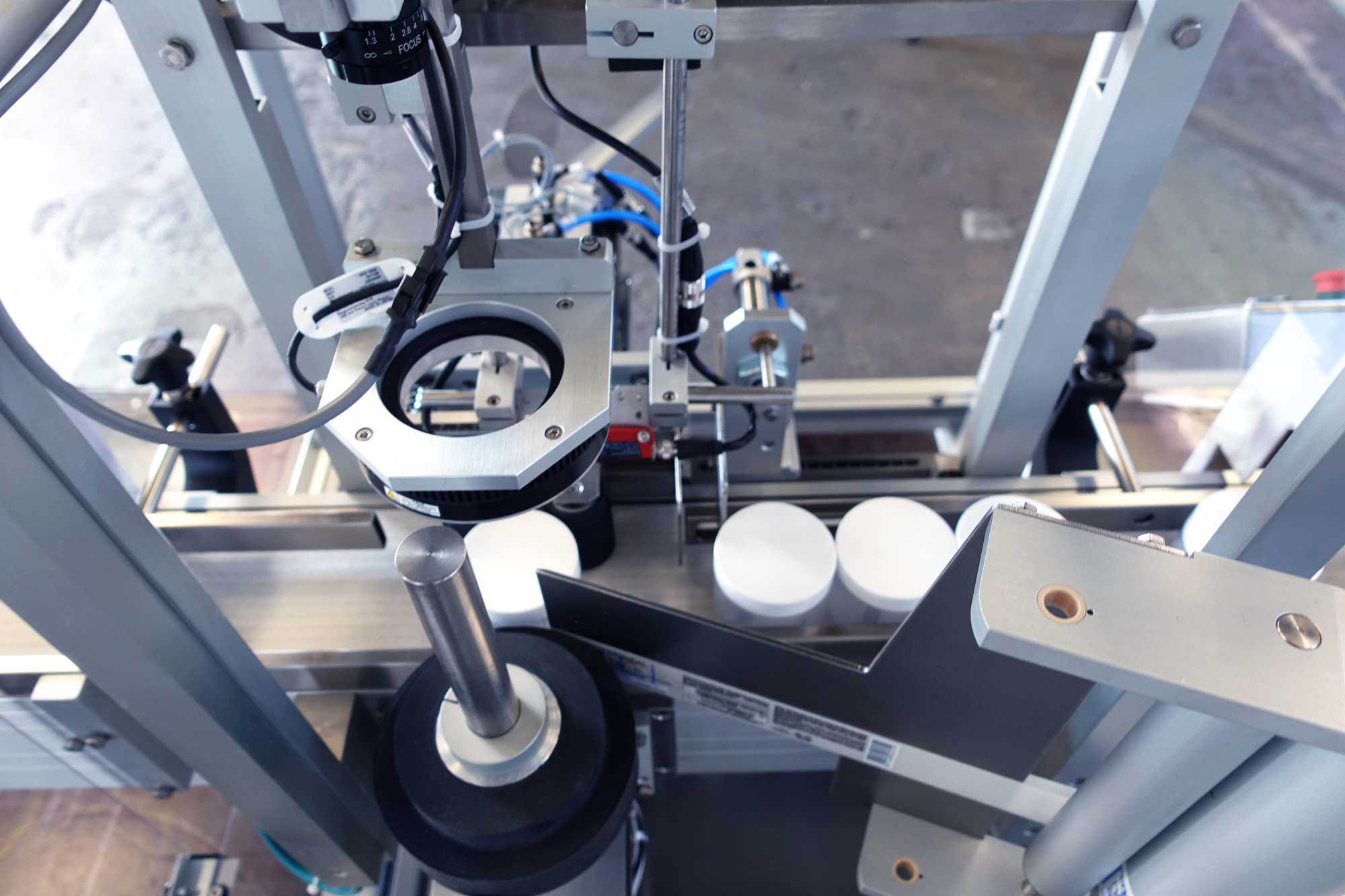

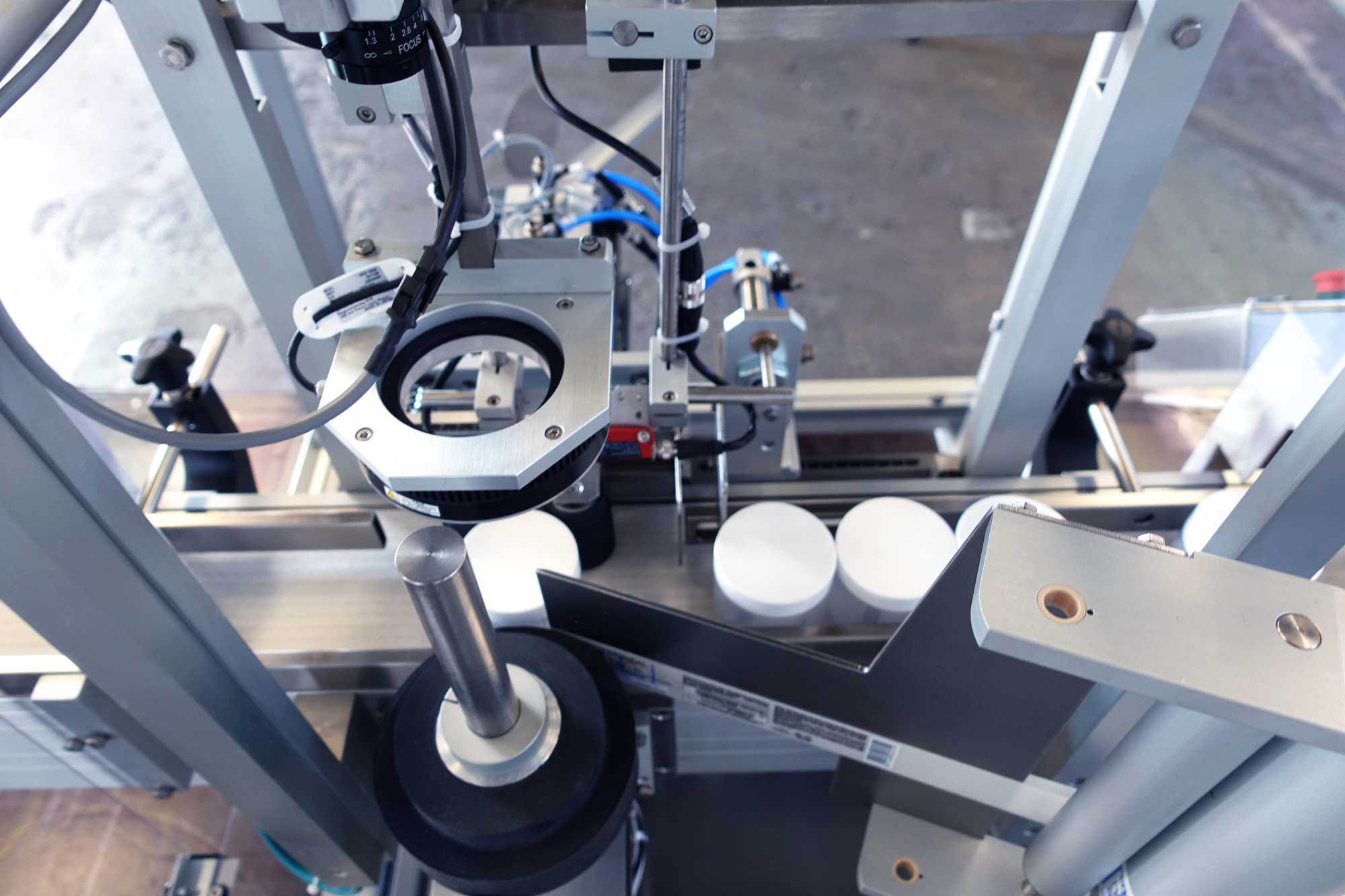

Special labelling System 1 Turning with a vision system for orientation and cap reading.

To achieve this goal, Etipack developed a customized system to apply a wrap-around label with orientation in relation to the cap or to another reference such as a brand or mark.

Precise and perfect wrap-around application for products in 3 sizes

The system allows the customer to handle wrap-around labeling of 3 product formats with maximum flexibility and accuracy, solving processing difficulties typical

of cylindrical products such as defects like air bubbles and label orientation. With the integration of a custom vision system and an orientation system, the machine enables the application of wrap-around labels that can be oriented based on the position of the cap or a desired point.

Products can be labeled at speeds of 45 pieces per minute in the case of non-oriented products and 25

pieces per minute in the case of orientation.

System features and configurations

- Escapement System It enables the flow of products to be properly managed by allowing the product to be labeled to pass through and holding subsequent products in the queue for the time required to perform the rotation and wrap-around application.

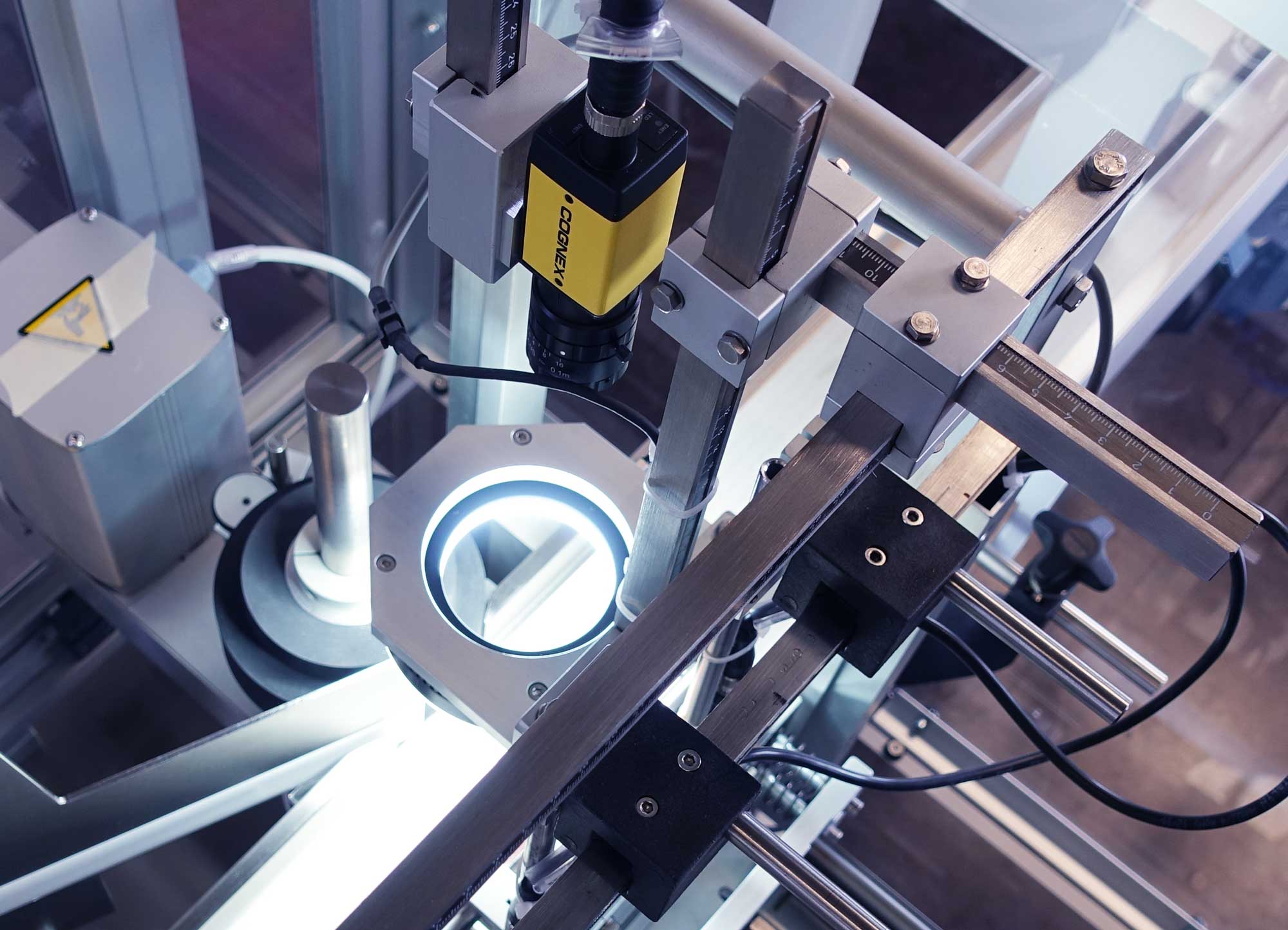

- Customized Vision System Equipped with a circular illuminator, it is designed specifically to read the position of the cap or a defined point of each cylindrical product. Its purpose is to perfectly position the self-adhesive label so that it is oriented according to the packaging cap.

- 3-roller orientation system to enable product rotation during labeling, the machine is equipped with a 3 opposed roller system. A large-diameter motorized roller and two opposed rollers connected to a pneumatic cylinder capture the product and perform rotation.

- 1 Energy 200 labeller. Equipped with feedback stepper motor drive, it achieves a dispensing speed of up to 50 m/min. It features a capacitive sensor inside the reel to detect the end of the backing paper.