Whizzy Step Motor automatic sheeter, sheet counter and flat product distributor

The friction feeder Whizzy is an automatic feeding machine for feeding and dispensing flat products that can be placed with the highest precision at a selected point.

The Whizzy Step Motor model is the most accessible of the friction feeders family thanks to the retrofitted stepper motor, and the integrated electronics that allow agile incorporation in production and packaging lines.

Flexible in terms of performance, accessories and available sizes, the friction feeder is equipped with a stainless steel and die-cast aluminum structure treated in Niplate® 600, which makes it also suitable for use in the food and pharmaceutical industry.

The friction feeder is very versatile and it covers a wide range of products, such as coupons, leaflets, greeting cards, stickers, package inserts, smart cards, sachets with thickness up to 3 mm, or 8 mm with a special configuration.

As for the other models of the series, the Whizzy Step Motor feeder is available in different widths and styles: with horizontal or vertical terminal and in widths Whizzy 210 and Whizzy 350, according to the maximum size of the product. It is also equipped with a display keyboard for advanced management of data exchange with the machine and the line.

Features of the feeder

| Features | 210 O - 210 V | 350 O - 350 V |

|---|---|---|

| Dispensing speed | Up to 80 m/min, pcs/min with product step | Up to 80 m/min, pcs/min with product step |

| Product sizes (width x step) | From 50 x 55 mm to 210 x 180 mm | From 50 x 50 mm to 350 x 180 mm |

| Product thickness | 0,2÷3 mm | 0,2÷3 mm |

| Product dispensing | Horizzontally (210 O) Vertically (210 V) | Horizzontally (350 O) Vertically (350 V) |

| Motor type | Stepper motor with feedback control system | Stepper motor with feedback control system |

| Size L - W - H | 687x402x660 mm (210 O) 451x402x880 mm (210 V) | 687x552x660 mm (350 O) 530x552x880 mm (350 V) |

| C.B. dimensions L - W - H | 400x200x600 mm | 400x200x600 mm |

| Power supply | 230 V, 50-60 Hz | 230 V, 50-60 Hz |

| Electrical input | 150 W | 150 W |

Features of the feeder

- Single product feed adjustable product loading stock

- Double shoulder structure in cast aluminum treated Niplate® 600

- Adjustable product loading stock. Loading also with sheeter in operation

- Fixed rear foot kit

- Feeding system with parallel rubberized belts

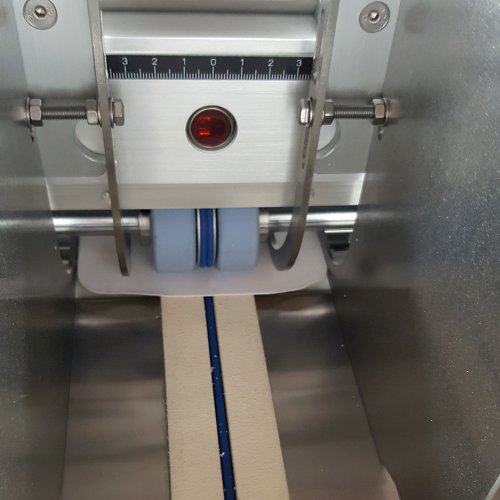

- Single product scraper with micrometric thickness adjustment

- Horizontal distribution terminal with overlapping flat belts

- Stepper motor with a feedback control system (speed 60 M/min)

- Stop sensor

- Integrated electronics

- Display keyboard for speed programming and counting; counted products collector (package creation)

- Product presence control

- Minimum load control in the stock

Ancillary devices

- Base support structure

- U-shaped support structure

- Encoder

- Stirrer kit

- Air Table