High speed automatic friction feeder

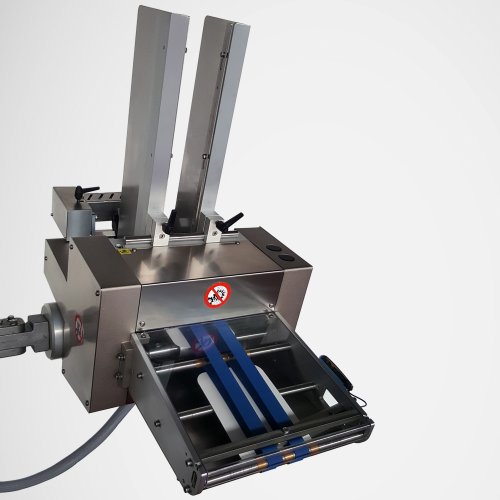

The Whizzy friction feeder is an automatic feeding machine for feeding and dispensing flat products that can be placed with highest precision at a selected point.

The Whizzy series represents the top choice for friciton feeder as far as performace, ancillary devices available and formats (lenghts and styles) and is ideal to integrate with OEM equiments and any packaging line where high-speed and precision are required.

The structure is entirely in stainless steel and this makes them ideal for applications in food and pharmaceutical packaging lines.

The Whizzy friction feeder is very versatile and can handle a wide range of products such es. coupons, vouchers, instruction sheets, pre-folded brochures, envelopes, promotional, folded, cards, with thickness up to 3 mm, with standard configuration, or up to 8 mm with customized setup.

The series of Whizzy friction feeders is available in a wide variety of widths and styles: with horizontal or vertical dispensing units, widths Whizzy 110, Whizzy 210, Whizzy 350, according to the size, with brushless motor, PLC electronics for advanced managment of data exchange betwen the feeder and the packaging line. They can feed individual products or in batches.

Features of the feeder

- Single product feeding machine

- Adjustable loading stack

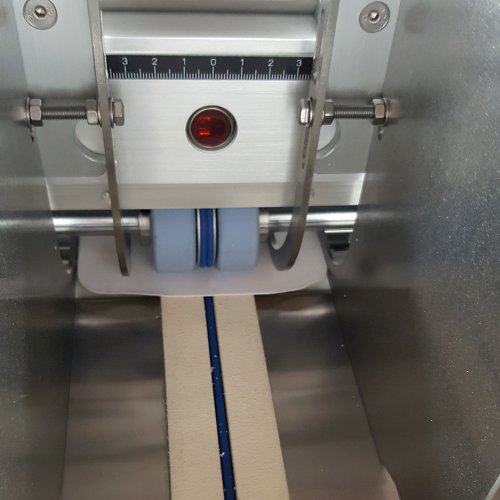

- Belt skimming system

- Flat belts dispensing units, horizontal or vertical

- Stop sensor

- Separate control box (remote terminal up to 3 m) with integrated PLC

- Separate control panel (remote up to 3 m)

- Control on minimum load

- Start/dispensing

- Controls and alarms

- Brushless motor

Ancillary devices

- Base support structure

- U-shaped support structure

- Encoder

- Programming keyboard for speed and counting

- Tray for counted products (collating function)

- Control dispensed product

- Loading stack for higher autonomy

| Features | 110 O - 110 V | 210 O - 210 V | 350 O - 350 V |

|---|---|---|---|

| Dispensing speed | ≤ 200 m/min (400 pcs/min depending on the product step) | ≤ 200 m/min, (400 pcs/min with product step) | ≤ 170 m/min, (300 pcs/min with product step) |

| Product sizes (width x step) | From 50 x 55 mm to 110x 180 mm | From 50 x 55 mm to 210 x 180 mm | From 50 x 50 mm to 350 x 180 mm |

| Product thickness | 0,2÷3 mm | 0,2÷3 mm | 0,2÷3 mm |

| Product dispensing | Horizzontally (110 O) Vertically (110 V) | Horizzontally (210 O) Vertically (210 V) | Horizzontally (350 O) Vertically (350 V) |

| Motor type | DC motor actioning | DC motor actioning | DC motor actioning |

| Size L - W - H | 700x300x935 mm | 700x402x760 mm (210 O) 550x402x900 mm (210 V) | 687x547x760 mm |

| C.B. dimensions L - W - H | 400x200x600 mm (110 O) 533x297x894 mm (110 V) | 400x200x600 mm | 400x200x600 mm |

| Power supply | 230 V, 50-60 Hz | 230 V, 50-60 Hz | 230 V, 50-60 Hz |

| Electrical input | 920 W | 920 W | 920 W |