Automatic bandolier feeder for bandolier packaging

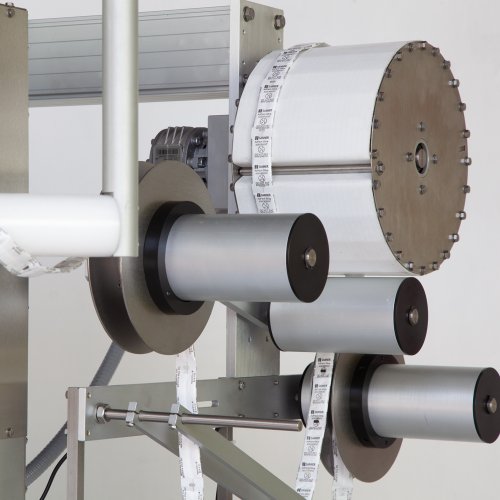

The automatic bandolier feeder Whizzy Cut & Feed is an automatic friction feeder for bandolier packaging; products may come on a reel or fanfolded.

The feeder automatically draws, cuts and feeds from a bandolier 2, 3 or 4 side sachets, flowpack sachets containing solid products, liquids, powders, grains or small 3D objects, e.g. stickers, food dressing, spices, dessicants, silica gel, creams, pharmaceuticals, gadgets, promotionals.

The feeder is equipped with a cutter providing a precise and neat cut at a chosen point by reading a notch, a hole or by ultrasound dectection.

The bandolier feeder Whizzy Cut & Feed can cut and feed sachets from 30 up to 180 mm in width and a tickness up to 10 mm, other features are available upon request.

Orbital version for high speed

The feeder is also available in Whizzy Cut & Feed Orbital version for high-speed processing. It is designed for productions above 120 pcs/min and up to 300 pcs/min.

Features of the feeder

| Features | |

|---|---|

| Dispensing speed | ≤ 60 m/min (130 pcs/min with bag dimensions of 40x40 mm and weight of 5 g) |

| Product sizes L | 30 - 180 mm |

| Product sizes W | 30 - 150 mm |

| Product thickness | 1÷10 mm |

| Product dispensing | Horizontally |

| Motor type | Brushless |

| Size L - W - H | 1215x1020x2030mm |

| C.B. dimensions L - W - H | 600x250x700mm |

| Power supply | 400 V, 3P-N-PE V 50/60 Hz |

| Electrical input | 1380 W |

| Electric protection | IP 54 |

Features

- Bandolier feeding

- Encoder for checking cutting pitch

- Control system on thickness

- Programmable brusheless motorized drawing module

- Brushless motorized cutter

- Stop sensor on product distribution

- Separted control box (remote terminal up to 3 m) with integrated PLC

- Separate control panel (remote up to 3 m)

- Brushless motor

Ancillary devices

- Base support structure

- Customized support structure

- Motorized feeding units