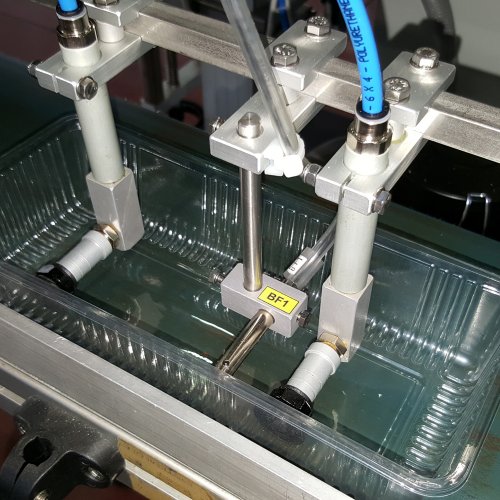

Denester for trays and lids

Clippy Denester is a denester machine, that is a pick and place device especially designed to denest thermoformed trays and lids.

Clippy Denester by a vacuum suction mechanism picks piled trays (lid, tubs) from a loading stacker add places them horizontally on the packaging line.

This denester is equipped with ad a double loading stack, in order to load 2 rows of products and increase production speed; upon request it is possible to add more loading stacks for even higher production needs.

The programming keyboard will allow to set speed and control functions in a user-friendly way: automatic speed adjustment, multiple product distribution, control of missing picking with automatic stop.

Features of the denester

- Base support structure

- Double loading stack (more loading stack upon request)

- Mechanical device with vacuum pad for horizontal positioning

- Control on missing picking

- Venturi vacuum pump

- Safeguards on kinematic

- Separate control box (remote terminal up to 3 m) with integrated PLC

- Separate control panel (remote up to 3 m)

- Brushless motor

Ancillary devices

- Start for tray picking and placing

- Control on minimum load

- Programming keyboard

- Vacuum pump (according to products)

| Features | |

|---|---|

| Dispensing speed | ≤ 100 pcs/min ((depending on the product shape and dimensions) |

| Product sizes L | 100 - 200 mm |

| Product sizes W | 100 - 200 mm |

| Product thickness | 10÷35 mm |

| Motor type | brushless |

| Size L - W - H | 1187x1958x1214mm |

| C.B. dimensions L - W - H | 400x600x200mm |

| Power supply | 400 V 3P-N-PE, 50-60 Hz |

| Electrical input | 600 W |

| Electric protection | IP 54 |