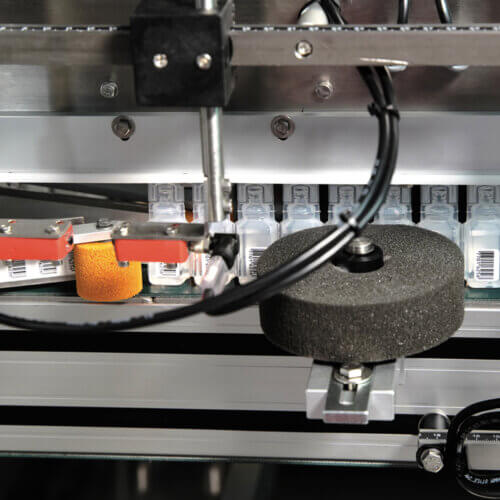

Automatic labelling system for side and front/back application

The System 5 series includes a range of labelling systems for the application on one side, or two sides (recto/verso) of elliptical and quadrangular products and Blow Fill Seal.

Labelling systems are fully automatic labelling machines with an integrated conveyor system; they are self-sufficient small labelling lines providing for conveying, handling and labelling. They can therefore be used both offline or connected to other packaging machines (e.g. filling machines).

Automatic labelling systems for recto/verso application are ideal for labelling of elliptical or quadrangular jars, bottles, Blow Fill Seal products and vessels made of plastic, glass, tin for the food, chemical , cosmetic and pharmaceutical market.

Multipack Solutions

They can also be employed to assemble multipacks of products such as wet wipes, potato chip bags or snacks, by means of a double label (front/back or top/bottom).

Modularity & integration

The series of Systems 5 provides different models, depending on production needs, the equipment of alarms and controls.

The systems provide different production speeds, in standard, customized or tailor-made configurations.

The modular design allows fitting, on a main machine body a variety of labelling machines of different width and speed, as well as a wide range of ancillary devices that complete the main functions providing for application on 1 side, on 2 sides (recto-verso) combined with top, bottom or tamper-evident , wrap-around labelling (with DRP device).

The system is compatible with different types of print units – hot stamp, thermal transfer, inkjet- manufactured by Etipack ad major manufacturers such as Markem, NOVEXX Solutions, Sato, HSA, Wolke, to print any codes, variable data and images.

Technical specifications

| Features | System 5 Active | System 5 Modular |

|---|---|---|

| Production speed | ≤5000 pcs/h, (with product step of 100 mm and label step of 80 mm) | ≤ 8000 pcs/h, (with product step of 100 mm and label step of 80 mm) |

| Dispensing speed | ≤ 20 m/min | ≤ 30 m/min |

| Type of product | Bottles with elliptical, quadrangular or round section shape | Bottles with elliptical, quadrangular or round section shape |

| Product size (width x step) | From 28 x 40 mm to 90 x 130 mm | From 28 x 40 mm to 90 x 130 mm |

| Product height | 50÷350 mm | 50÷380 mm |

| Label dimensions W | 30÷198 mm | 8÷198 mm |

| Label dimensions L | 10÷120 mm | 8÷250 mm |

| Outside reel Ø | ≤ 280 mm | ≤ 280 mm Standard ≤ 380 mm Optional |

| Inside reel Ø | 40÷75 mm | 40÷75 mm |

| Size L - W - H | 2500x2018x1492mm | 2581x2215x1761mm |

| Power supply | 230 V, 50/60 Hz | 230 V, 50/60 Hz |

| Electrical input | 1000 W | 1300 W |

| Compressed air | 6 bar (with print unit) | 6 bar (with print unit) |

Features of the labelling system

- Varnished steel machine chassis with panels in stainless steel

- Belt or table-top conveyor

- Automatic labelling machine

- DSP (product stabilizer device)

- Electric panel with display

- Display

Ancillary devices available

- Chain distancing/orienting device

- Encoder for automatic speed variation

- Safety protections

- Print units (thermal ink jet, thermal transfer, hot foil)

- Devices for wrap-around application

- Optional labelling machine for tamper-evident labelling

- Optional labelling machine for bottom labelling

- Controls and alarms