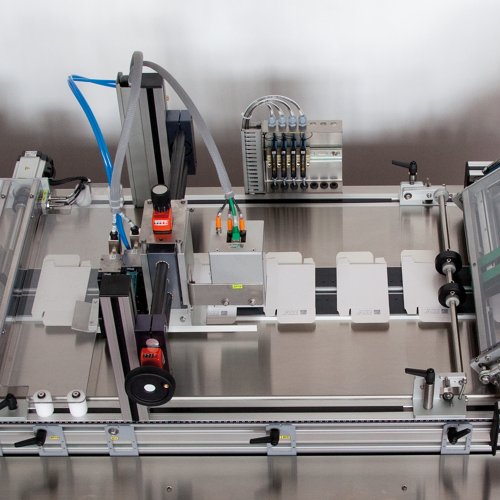

Automatic system for labelling, direct coding and serialization of pharmaceutical flat carton boxes

The pharmaceutical labelling machine System 9 Pharma is an automatic system providing for direct coding, labelling (application of bollino or vignette style label) and offline serialization of pharmaceutical flat boxes

This system can be equipped with friction feeders, labelling machines and print unit providing for carton feeding, labelling and printing of flat boxes as well as with vision systems for reading and checking data.

This system belongs to the Etipack Pharma line, especially dedicated to labelling, coding, serialization and track and trace of pharmaceuticals; this line has been designed to ensure high standards of quality, safety, productivity and maintenance complying with the guidelines for good manufacturing practice of pharmaceutical markets.

The Etipack Pharma line includes different labelling machines, labelling systems and friction feeders to handle a variety of products: ampoules, vials, boxes, syringes, single-dose, inhalers, Blow Fill Seal, inspection and inserting of information notices.

Features of the labelling system

- Machine frame with painted steel and panels made in stainless steel

- Continuous movement with servomotor and inverter

- Highly accessible for easy adjustments, inspection and maintenance operations

- Mechanical and electrical setup for serialization system (at choice)

- Control panel to operate the system

- Operating system by recipes through control panel

- Print unit (laser, thermal ink-jet, thermal transfer, hot foil)

- Printing control

- OCV/OCR control

- CFR 21 part 11

- Barcode control

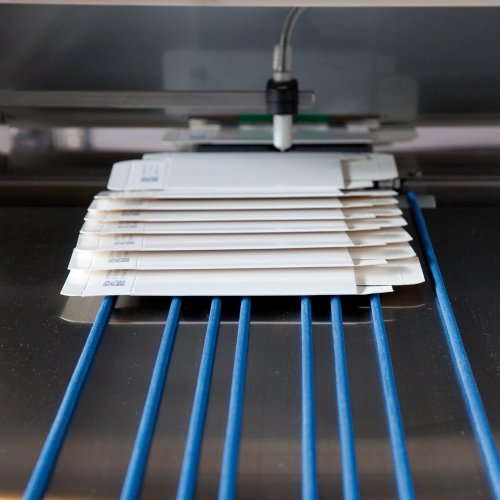

- Adjustable product stacker with shaving group with micrometric regulation, independent motorization with servomotor and inverter

- Double parallel belts product feeding device

- 3 colours light tower with buzzer to report the running state, alarms and warnings

- Motorized aligning kit

- Air ejection into separate unit

- Product collection unit

- Energy-saving function in case of inactivity

Ancillary devices available

- Safety guards on system.

- Labelling machine (with second module).

- Alternative downward product ejection, with separate unit

| Features | |

|---|---|

| Production speed | ≤ 400 pcs/min. * |

| Size L - W - H | 2942 x 850 x 2000 mm |

| Power supply | 400 V, 3L-N-PE 50÷60 Hz |

| Electrical input | ≤ 2000 W |

| Compressed air | 6 bar (with print unit) |

| |

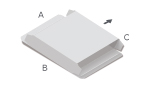

| A_Product size length (min.-max) | 60÷400 mm |

| B_Product size width (min.-max) | 50÷350 mm |

| C_Thickness (min.-max) | 0,5÷5 mm |

| * with box step of 80 mm |

|