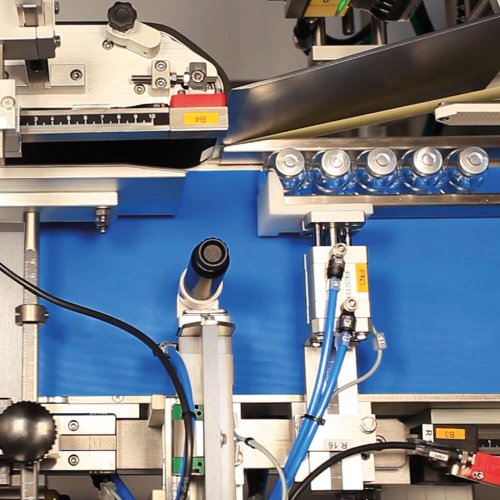

Pharmaceutical labelling machine the application of pressure-sensitive labels on vials and any cylindrical vessel

Pharmaceutical labelling machine for the application of self-adhesive labels on vials and cylindrical products

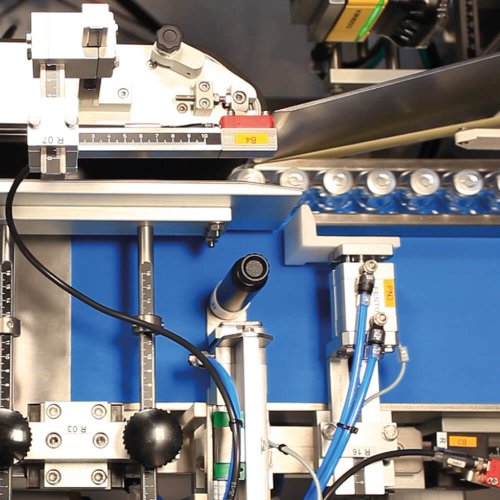

Pharma Round is an automatic labelling system specifically for the pharmaceutical sector designed according to GMP guidelines to offer the highest level of performance in the application and control of self-adhesive labels on cylindrical vials.

It offers high accessibility thanks to a special labeler with frontal reel loading on the operator side that facilitates management, inspection, and maintenance. It is equipped with a control panel with fail-safe PLC electronics, for the constant diagnosis of the peripheral devices and the management of the system through an HMI operator panel manufactured according to the FDA reference standards “CFR21 part11” and GAMP guidelines.

It is controlled by a UPS system for the correct management of the automatic shutdown in the event of a power failure and, thanks to SCADA software, allows system configuration and programming, monitoring and recording of activities on an SQL Express database that includes reports.

The system stands out for its high standard features for labelling control and reject management thanks to a labelling control station and an air jet station that ejects the products and a control device that certifies that the reject has occurred. Pharma Round can also satisfy different printing needs thanks to the predisposition to integrate different printing groups.

This system belongs to the Etipack Pharma line, specially dedicated to labeling, coding, serialization and track and trace of pharmaceuticals; this line has been designed to ensure high standards of quality, safety, productivity and maintenance complying with the guidelines for good manufacturing practice of pharmaceutical markets.

The Etipack Pharma line includes different labelling machines, labelling systems, and friction feeders to handle a variety of products: ampoules, vials, boxes, syringes, single-dose, inhalers, Blow Fill Seal, inspection and inserting of information notices.

Features of the labelling system

- Varnished steel machine chassis with panels in stainless steel

- Highly accessible for easy maintenance, inspection and service

- Control panel to operate labelling system

- Operating system by recipes through control pane

- Double conveyor system with variable and different working speed, with guides and rulers

- Automatic labelling machine with hybrid stepper motor with magnetic encoder, advance electronic with multitasking processor, internal capacity sensor for detecting label reel end

- Horizontal and vertical micro-metric adjustments

- Micro-metric adjustment of the overprint position on the label

- Minimum and maximum load control

- Label presence control system on products with luminescence photocells or camera

- Air blow ejection system with lockable tray for rejects and ejection control

- Signals for line operation

- Safeguard protections on conveyor system

- Electric board with 5″ touch screen control panel 2 colours light tower

- Quick compressed air releasing in case of emergency

Ancillary devices

- Choice of different printing units (thermal ink jet, thermal transfer, hot foil)

- Label skew control

- OCV/OCR control

- Barcode control

- Serialization system

- Ultra sound sensor for transparent labels

- Energy-saving function in case of inactivity

| Features | |

|---|---|

| Production speed | ≤ 24.000 pcs/h |

| Dimensioni L - La - H | 2498 x 1488 x 1847 mm |

| Size L - W - H | 230 V, L-N-PE 50÷60 Hz |

| Power supply | ≤ 1300 W |

| Electrical input | 6 bar |

| |

| A_Product size Ø (min.-max) | 18÷80 mm |

| C_Product size h (min.-max) | 45÷180 mm |