Automatic dispenser model for cutting and feeding sachets

DOWNLOAD CASE IN PDF

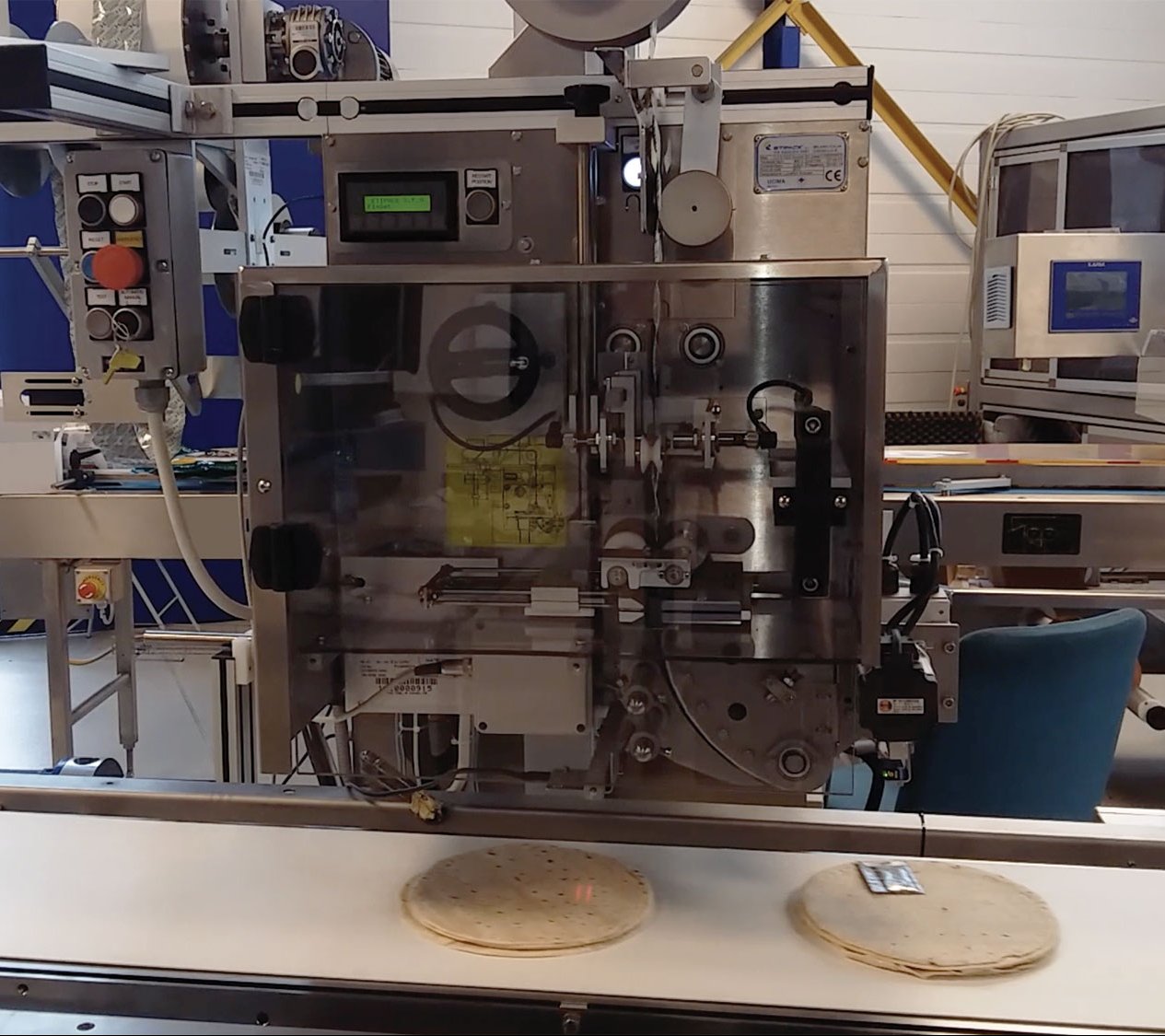

Automatic cutting and distribution system of Oxigen Scavenger sachets on a continuous line for the production of tortillas

Client company – One of the largest companies globally specializing in the production, distribution and sale of tortillas, tacos, corn chips and cornmeal.

The solution: Bandolier Feeder Whizzy Cut and Feed with motorized terminal for alternate distribution and cutting

The customer, a manufacturer and distributor of food products, needed to insert inside a flow pack, containing more tortillas, one or two sachets of Oxigen Scavenger, an oxygen absorbing sachet very suitable for the food industry. In order to achieve this objective, Etipack has designed a machine with a motorized module capable of cutting and feeding on a continuous strip the sachets made from a reel.

The peculiarity of the machine

The special feature of the machine is that it is able to cut and distribute all the sachets of the reel before this one becomes unusable.

System features and configurations

- Whizzy Cut and Feed with a motorized terminal, the machine can distribute and cut 150 pieces per minute. It is designed to distribute sachets on a continuous line by placing them horizontally on the packaging line.

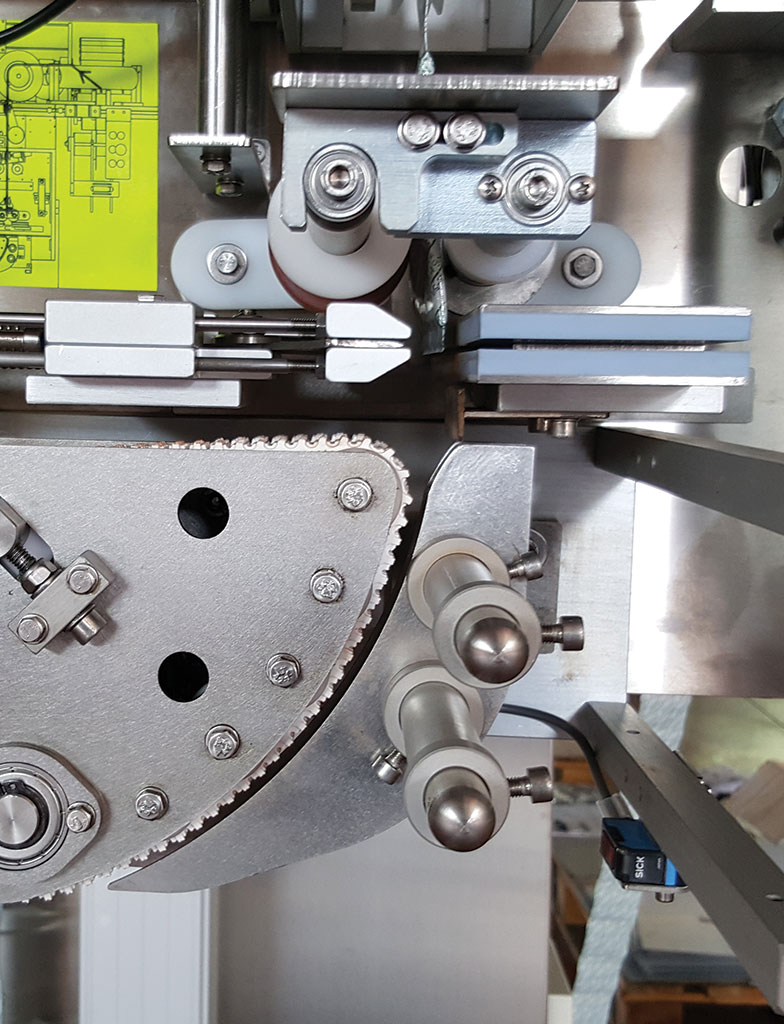

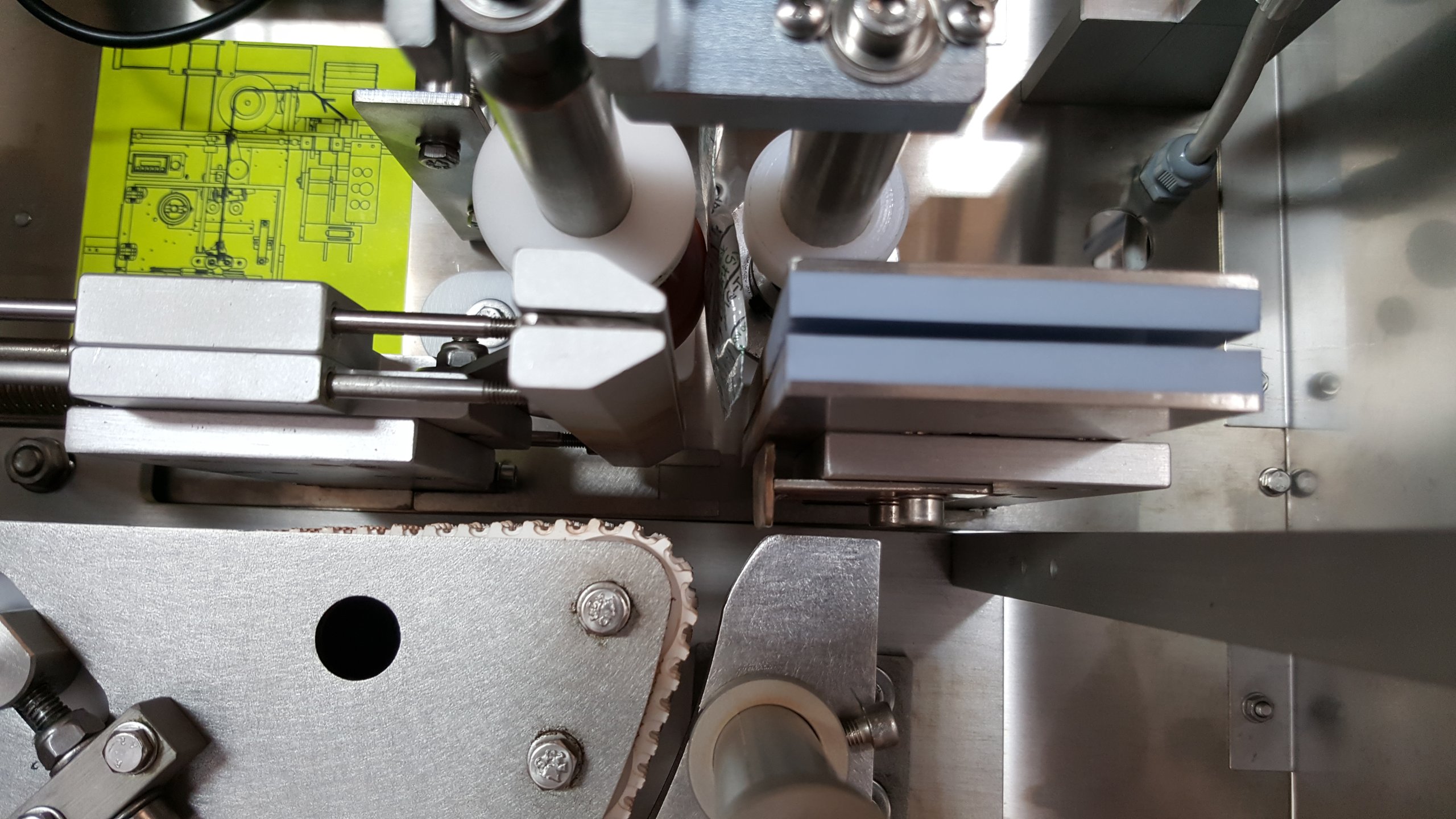

- Motorized cutting system The motorized cutting system on electric axis allows high speeds, performing the cut in a short stop of the towing group, creating a serrated cut in order not to create waste even on the most critical products. The electric axis is in phase with the motor that carries out the towing, in order to have the cut sachet perfectly matched perfectly match with the underlying product.

- Safety system The machine is equipped with protection guards that cover the moving mechanical parts and with plexiglass doors with safety microswitch.

- Motorized unwinder module this system, in aid of the Cut & Feed, manages the product from the reel, making a single strip of product to the haul-off unit. The separate motorization unwinds the reel by unloading its weight through a secondary motor.