Horizontal labeling of multi-pack wet wipes for CB Packaging

DOWNLOAD CASE IN PDF

Customized labelling machines Energy 300 for horizontal application of self-adhesive labels on multi-packages

A.P.I. S.R.L – CB PACKAGING – a company specialized in the production of machines for the packaging of disposable hygienic products-, was looking for a system to be integrated into the line, for the labeling of multi-pack wet wipes.

The challenge: Implementing a suitable labelling system to reduce the use of plastic packaging on multi-packs of wet wipes

“A.P.I.’s need was to optimise the demand for a particular packaging system”, says Vice President Pierbattista Maglio. The company was looking for a tailor-made system for the labelling of multi-pack wet wipes to be integrated into the packaging line commissioned by a manufacturer of personal care products. The aim was to find a solution that could avoid the use of secondary plastic packaging to assemble individual packs of wipes. This particularity determined the need to completely revolutionise the product labelling logic. It was necessary to switch from a standard vertical application, to a horizontal application in order to be integrated into the line designed by A.P.I for horizontal product loading and handling.

The solution: customized Energy labellers to apply a top and bottom label horizontally to obtain multi-packages

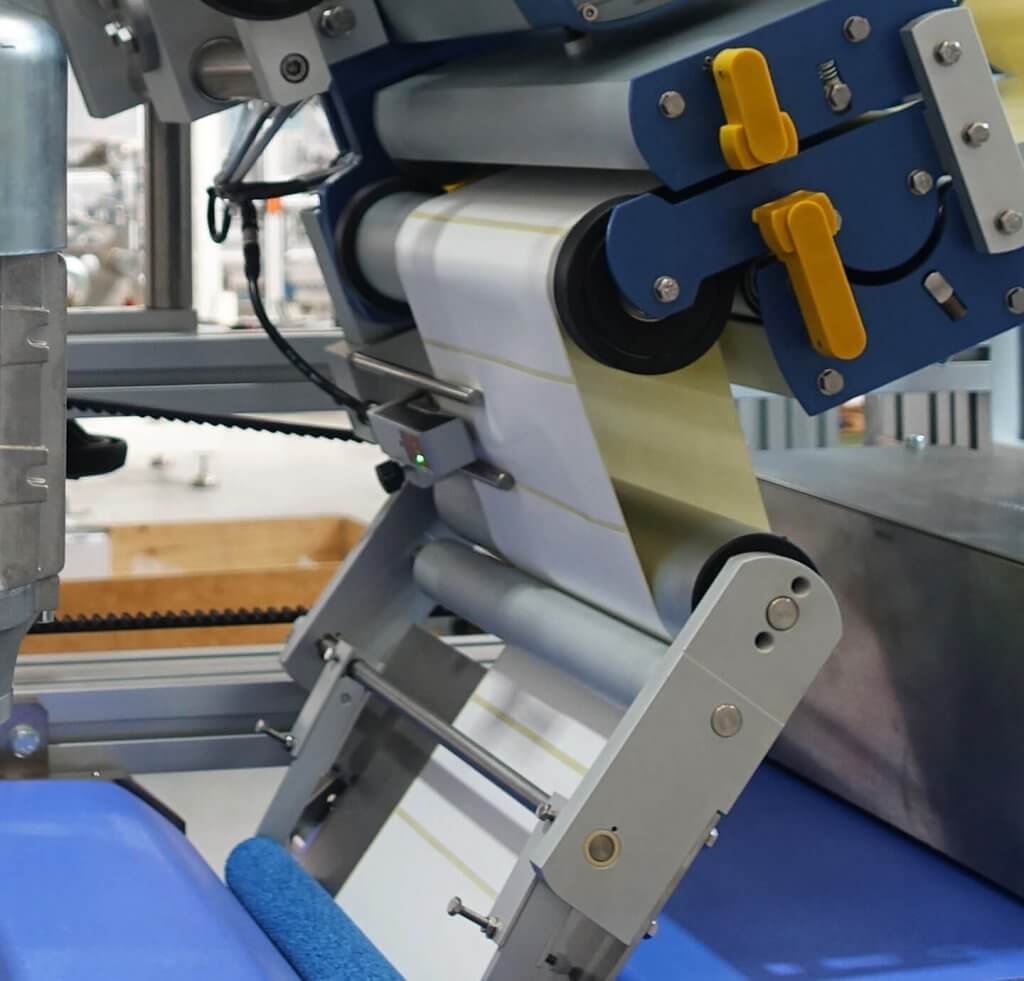

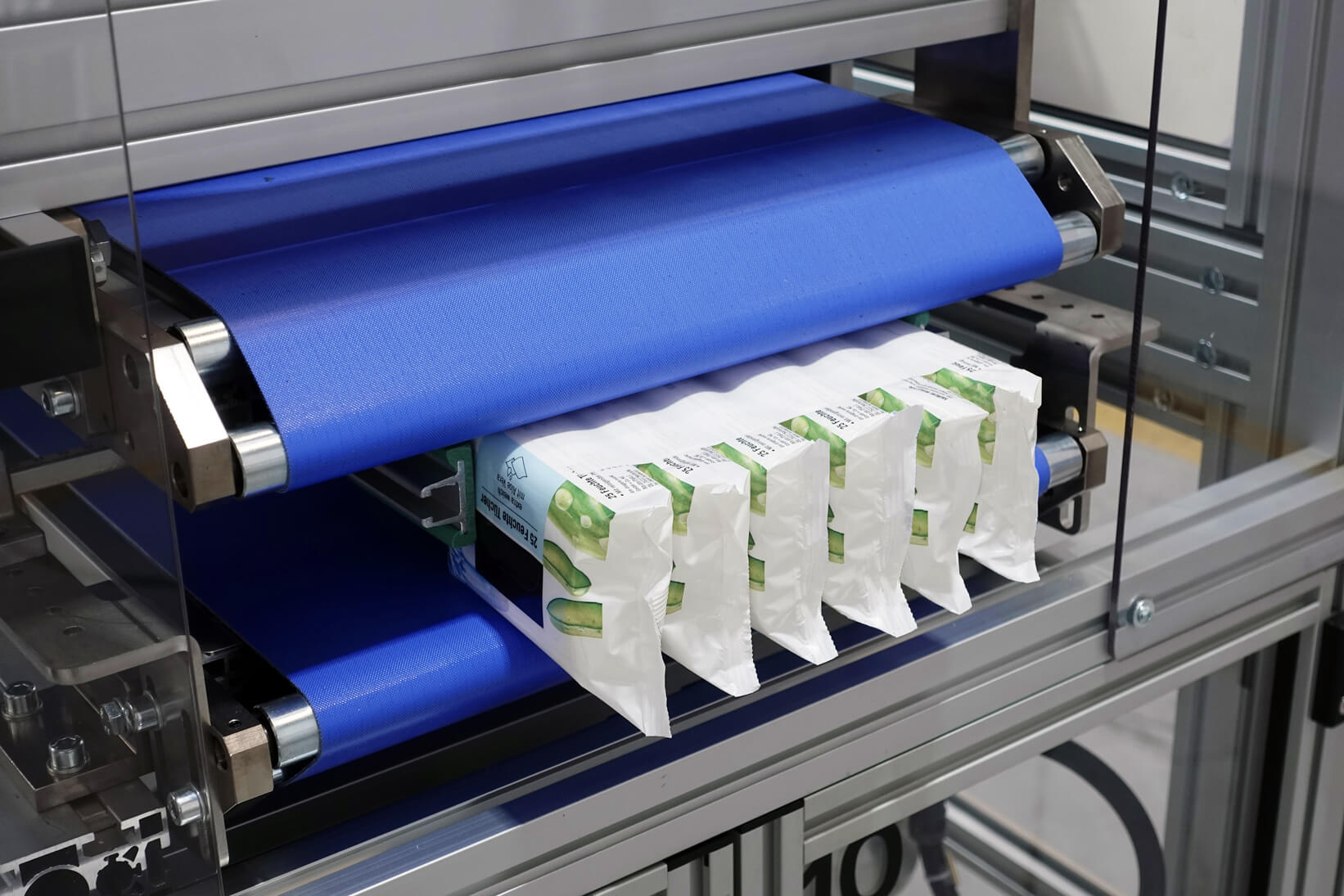

To achieve the required result, Etipack designed two tailor-made Energy labelers which, positioned at the end of the line in two stations – above and below the conveyor belt – carry out simultaneous product labeling. As a batch passes over the conveyor belt, the labelers apply two labels, one on the top and one on the bottom of the packs, allowing 5 packs of wet wipes to be assembled into a single multi-pack. The solution therefore completely eliminates the need for additional packaging. The system allows the use of large labels up to 200 mm long and 298 mm wide and achieves a distribution speed of up to 20 m/min.

System features and configurations

- Customized applicators – laced between the conveyor belts of the line designed by the customer, allow the upper and lower application of labels on the product.

- Photostop – the ultrasonic photoelectric sensor located on the support bar enables detection of the label pitch even in see-through plastic.

- Encoders and start photocells – the start photocells on the line are synchronized with the labelers, and, thanks to an encoder installed in the lower part of the belt, they detect the start by reading the product, allowing the label to be distributed at the same speed as the belt.

- Special unwiders and rewinders – The unwinder, designed to accommodate reels with a 280 mm diameter and 300 mm width, is equipped with a dedicated front with a special front reinforcement to support the weight of the reel. The rewinder is designed to facilitate the removal of the backing paper by releasing the tension of the rewound backing paper.

- Front reinforcement – equipped with a quick-release handle, facilitates reel change.

- double dancer roller – It supports the smooth running of the label strip and maintains constant tension. It prevents the label from peeling when unwinding the reel, and continuous and abrupt paper swing.

Results: horizontal Labelling for multi-package thanks to top and bottom application of large-format labels

Thanks to the system designed by Etipack, A.P.I. – CB Packaging has built a tailor-made system for its customer, which allows individual packs of wet wipes to be handled, and assembled horizontally into a single multi-pack using labeling as a packaging method. The system thus eliminates the use of additional packaging, and consequently, it reduces the use of plastic, ensuring, on one hand, significant cost savings and, on the other hand, a significant reduction in the impact of products

on the environment.