How to choose the most suitable Friction Feeder to insert leaflets, coupons and other formats into product packaging.

Leaflets, drug-facts labels, heat-sealed sachets, small gadgets, but also collars on the neck of bottles and bottles, are widespread packaging complements included in a very large number of products. How to choose the most suitable technological solution to integrate in production and packaging process? Let us find out the differences and strengths of Whizzy and Mini Whizzy friction feeders, two major models in the Etipack range.

What to evaluate when choosing the friction feeder best suited to your needs

There are several useful aspects to choose the most suitable friction feeder for the integration of flat objects into the production process. Surely it is important to evaluate how many types and formats will have to be managed, what are the required production standards, and, finally, what sizes are available within the line. These aspects are essential to navigate between different models and categories of machinery available on the market.

Friction feeders in comparison: distinctive features of Mini Whizzy and Whizzy models

Mini Whizzy is the most compact automatic friction feeder in the Etipack line; a machine with essential features ideal for handling small format flat products, between 50 and 150 mm wide, up to 10 mm thick. It is therefore perfect for distributing even products thicker than a piece of paper, such as folders, packs of cards and sachets, cards and CDs with cases.

The product distribution can reach average speeds, up to 60 m/min, and takes place with a horizontal applicator that can be reloaded from a manually adjustable loading stack.

Thanks to its very small size, the Mini Whizzy friction feeder has the great advantage of being able to be more easily fitted into different packaging lines types and is a good choice to distribute medium thickness products in standardized productions that do not require high flexibility and processing speed.

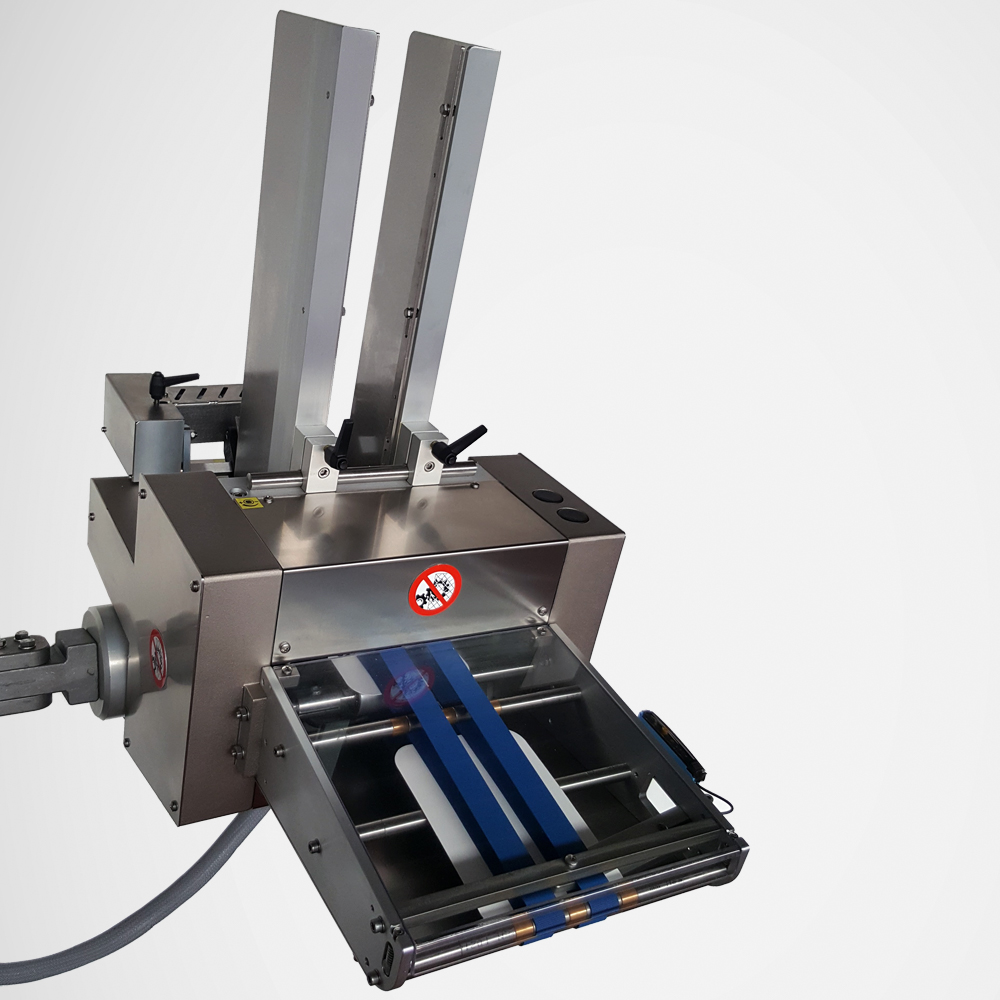

Whizzy is the most versatile and complete automatic friction feeder in the Etipack range; a machine with high functionality ideal for accurately positioning a wide range of thin and very thin products with a thickness between 0.2 and 3 mm.

The product distribution can reach high speeds, up to 200 m/min, and takes place with flat belt distribution applicators, both horizontal and vertical, which can be reloaded from an adjustable loading stack.

Thanks to the several configurations available, depending on the maximum size of the product to be processed – with horizontal or vertical terminal, in different widths 110, 210 and 350 mm – and a wide range of customizations and options, it can meet the most complex processing requirements. Equipped with brushless motorization and electronics with PLC for advanced management of data exchange with the line, it allows maximum control of all functions. The Whizzy friction feeder is the ideal choice for feeding and dispensing thin products in complex productions with high flexibility, integration, and processing speed requirements.

Learn more about Whizzy

Learn more about Mini Whizzy