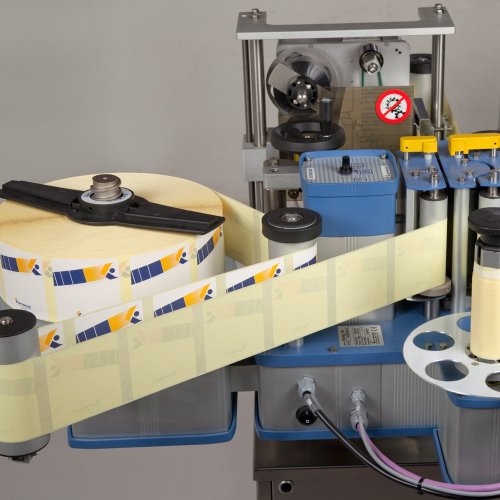

Wrap-around labelling system for bottles, jars, jars, bottles and cylindrical containers with speed from 50 to 200 pieces / minute

The System 1 series includes a range of automatic label applicators for wrap-around applications on cylindrical products.

Labelling systems are fully automatic labelling machines with an integrated conveyor system; they are self-sufficient small labelling lines providing for conveying, handling and labelling. They can therefore be used both offline or connected to other packaging machines (e.g. filling machines).

Automatic wrapping systems are ideal for labelling cylindrical jars, bottles, vessels, products made of plastic, glass or metal containing food, chemicals and cosmetics.

For wrap-around labelling of bottles, vials and ampoules for pharmaceutical markets you can visit the section devoted to pharmaceutical labelling machines of Etipack Pharma line such as System 1 and Etifiale.

System 1 also applies warranty seal labels on cylindrical jars of various sizes. The label, shaped to incorporate the seal, is applied in a simple and effective way.

The series provides different models, depending on production needs, the equipment of alarms and controls.

The systems offer production speeds from 50 up to 200 pcs / min, in standard configurations, or higher for customized or tailor-made labelling systems.

The modular design allows fitting, on the main machine body, labelling machines of different width and speed, as well as a wide range of ancillary devices that complete the main functions providing complete wrap-around labelling, labelling on tapered products, tamper-evident labelling.

The system is compatible with different types of print units – hot stamp, thermal transfer, inkjet- manufactured by Etipack ad major manufacturers such as Markem, Datamax-Honeywell, Sato, HSA, Wolke, to print any codes, variable data and images.

For wrap-around labelling of pharmaceutical vials and am poules please visit our section for pharmaceutical labelling machines, e,g. System 1, Etifiale

Features

| Features | SYSTEM 1 TWIST | SYSTEM 1 MODULAR | SYSTEM 1 TURNING |

|---|---|---|---|

| Production speed | ≤ 3000 pcs/h (with bottle Ø of 50 mm and label step of 100 mm) | ≤ 12000 pcs/h (with bottle Ø of 40 mm and label step of 100 mm) | ≤ 1500 pcs/h (with bottle Ø of 60 mm and label step of 150mm) |

| Dispensing speed | ≤ 15 m/min | ≤ 40 m/min | ≤ 20 m/min |

| Product size W | From Ø 20 mm to Ø 100 mm | From Ø 20 mm to Ø 80 mm | From Ø 20 mm to Ø 80 mm |

| Type of product | Cylindrical products | Cylindrical products | Cylindrical products |

| Product height | 40÷200 mm | 45÷200 mm | 45÷200 mm |

| Product size (width x step) | From 8 x 8 mm to 98 x 250 mm | From 8 x 8 mm to 98 x 250 mm | From 8 x 8 mm to 98 x 250 mm |

| Outside reel Ø | ≤ 280 mm | ≤ 280 mm optional ≤ 380 mm | ≤ 280 mm optional ≤ 380 mm |

| Inside reel Ø | 40÷75 mm | 40÷75 mm | 40÷75 mm |

| Size L - W - H | 1587x1358x1243mm | 2551x1463x1147mm | 2581x1536x1501mm |

| Power supply | 230 V, 50/60 Hz | 230 V, 50/60 Hz | 230 V, 50/60 Hz |

| Electrical input | 700 W | 1300 W | 1300 W |

Features of the labelling system

- Varnished steel machine chassis with panels in stainless steel

- Belt or table-top conveyor

- Automatic labelling machine

- DRP (product rotation device (for wrap-around labelling)

- Electric panel with display

Ancillary devices

- Encoder for automatic speed variation

- Safety protections

- Print units (thermal ink jet, thermal transfer, hot foil)

- Devices for complete wrap-around application

- Device for tapered products

- Optional labelling machine for tamper-evident labelling

- Controls and alarms