Industrial labeling of car brake pads with Nova Design Automazioni

Custom Energy 300 labeling machine for the application of pressure-sensitive labels on the upper part of brake pads

* In partnership with Biltek

Nova Design Automazioni, a company specialized in industrial automation and the design of cold forming moulds, was looking for a system for labelling car brake pads, to be integrated within the production line.

The challenge: handle double-sided labels with different orientations, and apply them with maximum precision in a given position

The client’s need was to find a solution that would allow them to “apply different types of labels on the brake pads processed by the machine, characterised by different lengths and orientation, which required the label to be oriented in different ways, at 90° and 180° with respect to the direction of unwinding and removal” says Daniele Bruno, owner of NDA. This requirement was due to the need to manage the application of labels from different manufacturers, each with a different orientation on the backing paper. Given the small application area on the pads, which have mounting holes, the solution required the highest degree of precision, as well as integration, with the rotary table, located in the production line.

The solution: customised labelling machine for label removal with 90°, -90° and 180° rotations, and application

in fixed position

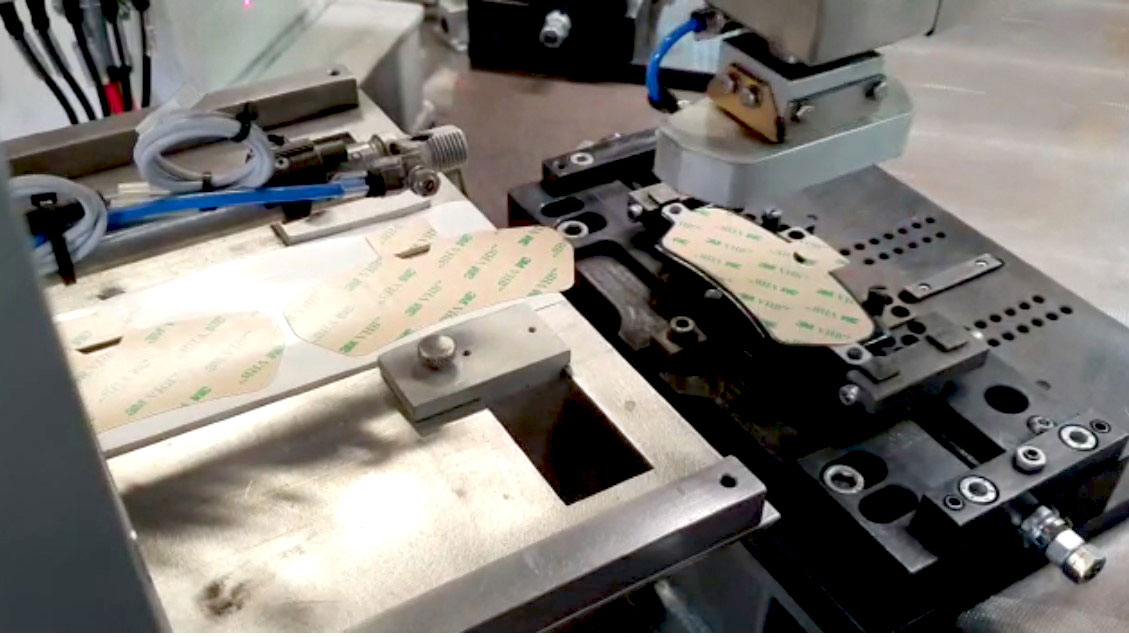

To achieve the requested goal, Etipack designed a labeler capable of performing rotations of +90°, -90° and 180° in order to pick up labels positioned in different orientations (vertical and horizontal) on the backing paper, and apply them in a fixed position (horizontal) on brake pads without affecting the machine configuration. The solution ensures a high level of precision given the small surface area on the product placed on a rotating table, therefore subject to pre-set movement.

System features and configurations

- distribution applicator customised with a second support bar to give the system more robustness and provide more support during production

- retractable blade advances and retracts to bring the label closer to the pad, facilitating pick-up and ensuring greater accuracy

- precision applicator with a maximum deviation between 0.3 and 0.5 mm.

- reinforced roller prevents label unwrapping when unwinding the reel.

- rotation device special motorised device with protection, performs rotations of + 90°, – 90° and 180° to pick up the label and apply it in the fixed brake pad position, placed on the rotating table. It allows the removal of labels of different brands, characterised by different layouts on the backing paper, while keeping the application position fixed.

- pneumatic applicator with transverse micro-adjustment, double-rod pneumatic cylinders, back pressure and cylinder reversal sensor, “bridge” support structure.

- maniglie di regolazione of the applicator on the precision blade allow centring without displacing the unwinder plates, interrupting the process and bringing it back in-line.

The results: precise and effective application on a fixed position, of labels with different orientations

he aspects that NDA particularly appreciated in the implementation of the project were: “knowledge of the production process and the product, in a particular application context, made it possible to provide a reactive solution to the many aspects that distinguish this project with its numerous peculiarities” – DB.

The feedback: working with Etipack

The main motivating reasons for NDA to choose Etipack were experience and diffusion of machines in the field of application of labels on brake pads”. The working methodology was also positively evaluated: “the project and the application, were the result of the constant exchange of solutions between NDA and Etipack, as collaboration is the basis of the relationship between two partners”– DB.