Pharma Flexi ultra-high-speed pharmaceutical labeling machine for cylindrical, even unstable products

The range of industrial labeling machines in the Etipack Pharma line dedicated to the pharmaceutical sector has been enriched with the new Pharma Flexi model an automatic labelling system designed to label, in a single solution and at very high speed, different types of pharmaceutical products of cylindrical format.

Maximum adaptability to accommodate size changes and specific configurations for vials, bottles, carpules, and syringes

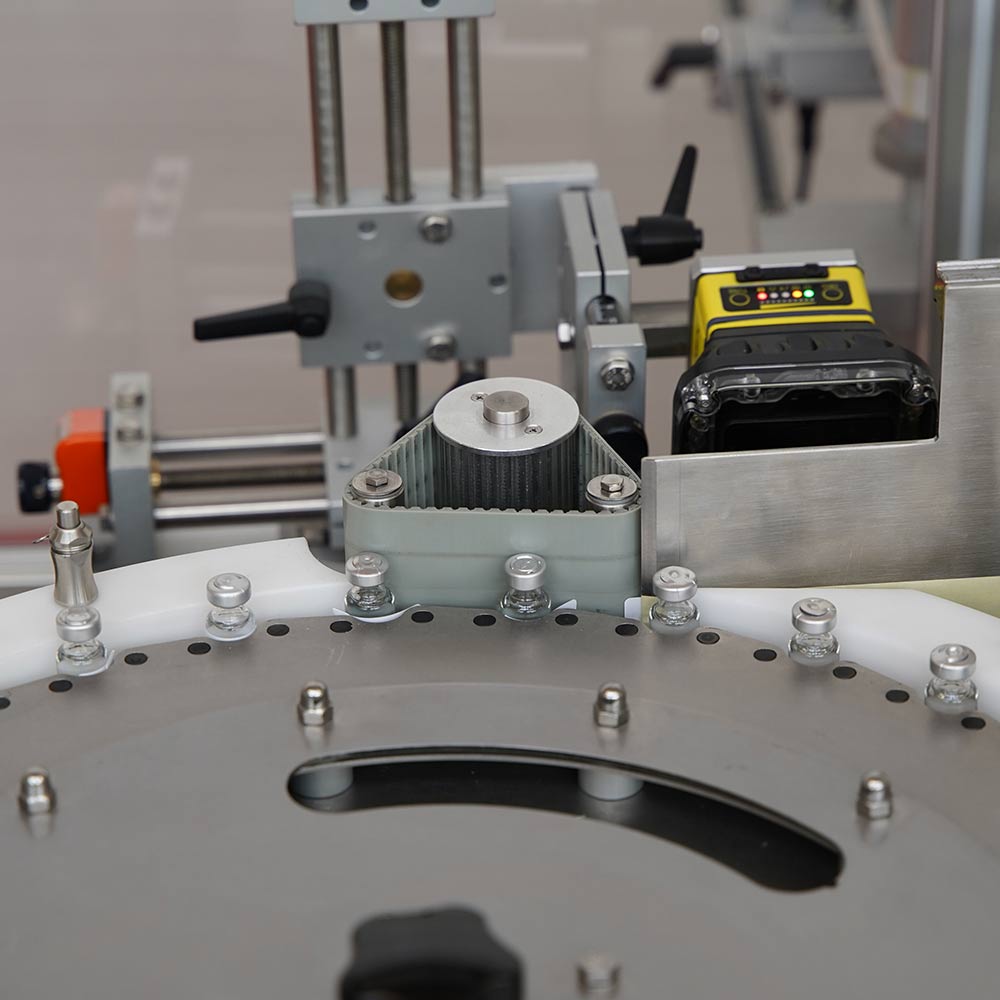

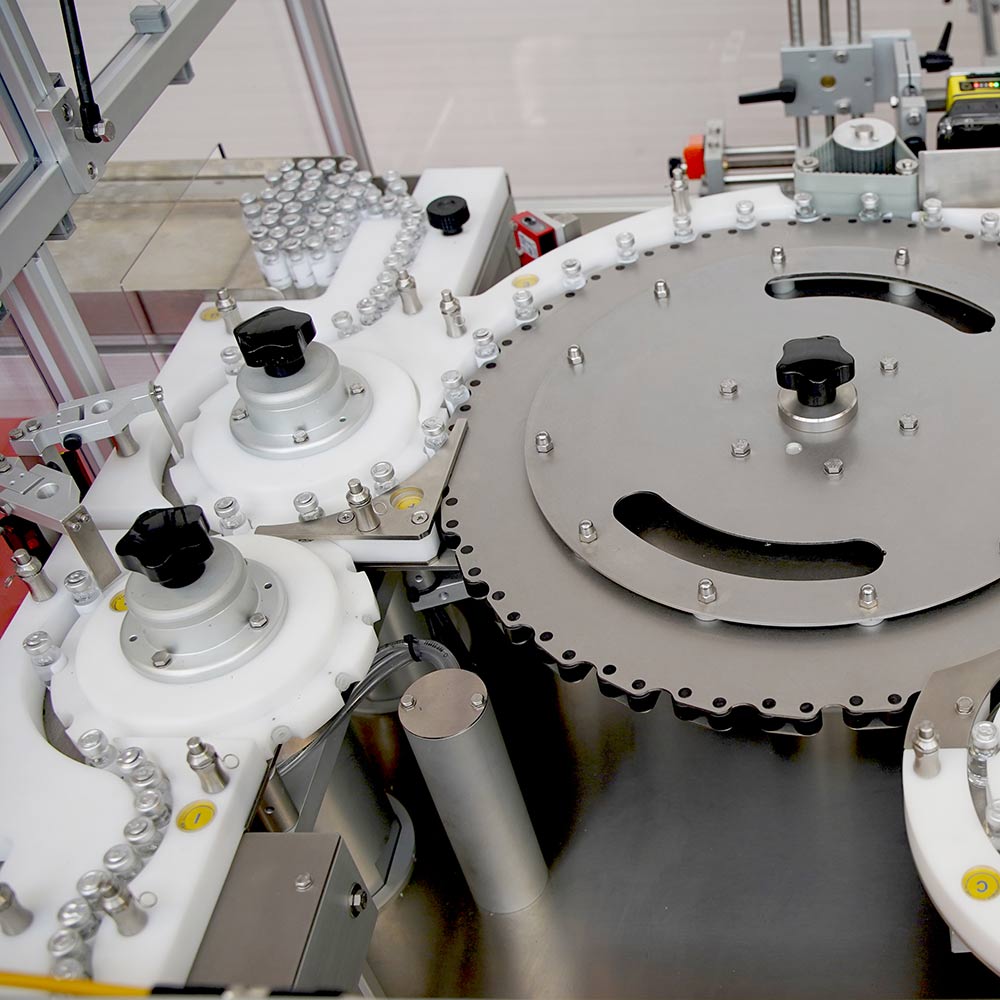

Pharma Flexi is designed to offer the market an innovative product that encompasses the latest developments in Etipack systems dedicated to pharmaceutical labeling of vials and bottles. It is a rotary system that consists of an infeed belt for product loading, an auger for spacing, and a transport and phasing system to properly contain the product during labeling.

The power of the new system lies in the perfect combination of labeling speed, ease of format changeover, and integration options that make it significantly competitive in the range of systems used for industrial pharmaceutical labelling.

Pharma Flexi can reach speeds as high as 400 pcs/min dependent on the customer’s format and line requirements and is designed to facilitate format changes, thus providing greater versatility in processing products with similar characteristics that allow compatible machine configurations. In fact, the system is designed to accommodate format changes for four types of products: vials, ampoules, carpules and syringes. As with all Etipack systems, Pharma Flexi enables tool-less format changeover by quickly and easily replacing the auger, double inlet loading stars, main handling star, double product discharge stars and guides.

Flexibility is the key word. Pharma Flexi satisfies both in-line and stand-alone production demands

Another key asset of the system is the capacity to operate either off-line or integrated into the production line. In fact, the presence of the auger makes it possible to insert and harmonize the movement of the products, containing and accompanying them towards the carousel, thus allowing very high labeling speeds to be achieved. The rotary conveyor system, in fact, provides the advantage of being less sensitive to product height, which, even if unstable, is stabilized. On the other hand, when used in stand-alone mode, Pharma Flexi is equipped with a low-grip conveyor belt for loading products to allow manual de-traying and related traying system for compliant and non-compliant products.

Cutting-edge electronics, remote controls, and ergonomics for precise and intuitive operation

With regard to the management and control of inspection and maintenance functions and operations, Pharma Flexi offers high autonomy and flexibility. The special control panel, with pivoting arm, is designed to offer maximum operability. Equipped with advanced electronics with Siemens S7 PLC for constant peripheral diagnosis according to industry requirements, The panel offers the ability to consult electrical diagrams and instruction manual and to better manage maintenance processes. Designed according to GMP guidelines, it also allows management of FailSafe functions, production batch and collection of CFR21/Event/Alarm reports and production data

Top-level labelling thanks to the highest accuracy and control standards in application and reject management

Pharma Flexi features a special, Kanigen-coated, high-production labeling machine specifically for the pharmaceutical industry. Positioned outside the guards, it provides high accessibility thus facilitating handling, inspection and maintenance operations.

Equipped with feedback stepper motor drive with magnetic encoder, it achieves a dispensing speed of up to 60 m/min. and can handle labels up to 100 mm. wide and load reels up to 380 mm. in diameter. The ergonomic touch screen display allows configuration of more than 50 operating parameters, as well as saving custom configurations. The same parameters can be remote-controlled on the labeling system panel. The special retractable blade positioned at the labeling point enables precise and smooth application of the label to the product body.

The versatility of the system also emerges from the standpoint of printing and variable data control possibilities: the Pharma Flexi labeling machine features a station for the control of successful labeling with a UV barrier. It is also set up to integrate a printing unit for variable data overprinting and the subsequent vision system for barcode and/or OCR/V overprinting control.

Another key feature is the advanced reject management. The system features two unloading stations for products which are conditioned thanks to a double outlet star, with a suction system and fail-safe function, which conveys them to either the rejection station, or to the conforming products station, thus allowing proper sorting. Products are collected statically using two dedicated trays with presence and maximum load controls.