High speed rotary pick and place

Clippy Rotary is a Pick and Place device with rotary movement that, thanks to vacuum pads, picks products from a loading stack and places them horizontally on a packaging line.

The rotary movement of Clippy Rotary is especially designed to meet the requirements of highest productivity with an output speed up to 400 pcs/min. as weel as of large autonomy thanks to a horizontal loading stack equipped with a control on minimum load.

The Pick and Place is ideal to dispense flowpack sachets, 2, 3 and 4 side sachets, coupons, cards and flat boxes made of non-porous materials.

The programming keyboard, in the brushless version, will allow to set speed and control functions in a user-friendly way: automatic speed adjustment, multiple product distribution, control of missing picking with automatic stop.

Technical Specifications

| Features | |

|---|---|

| Dispensing speed | ≤ 400 pz/min (depending on the product dimensions) |

| Product sizes L | 50- 120 mm |

| Product sizes W | 50- 150 mm |

| Product thickness | 0,1÷1,5 mm |

| Motor type | brushless |

| Size L - W - H | 2416x2115x839mm |

| C.B. dimensions L - W - H | 400x600x200mm |

| Power supply | 400 V 3P-N-PE, 50-60 Hz |

| Electrical input | 690 W |

| Electric protection | IP 54 |

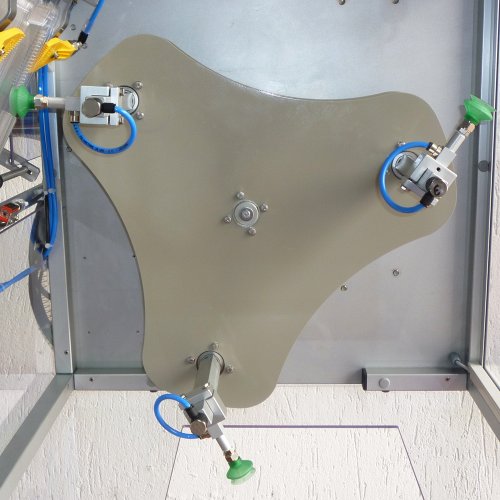

Features of the rotary placer

- Kinematic mechanism with rotor at 3 positions

- Vacuum pads with independent electrical drive

- Venturi vacuum generator

- Turbine vibrator

- Horizontal loading stack 1300 mm long

- Encoder

- Electro-pneumatic system

- Control on missing picking

- Safeguards

- Separate control box (remote terminal up to 3 m) with integrated PLC* (brushless version)

- Separate control panel (remote up to 3 m)

- Brushless motor

Ancillary devices

- Start for product picking and placing

- Programming keyboard

- Vacuum pump (according to products)