How to choose the most suitable industrial labeling machine to automate product labeling

Where there is a product there is (almost) always a label

Whether small, large, rectangular, square, see-through, polished, or matte, labels are inextricably tied to the production and packaging processes of almost all products available on the market. From food to pharmaceuticals, from cosmetics to paper products, there are countless sectors that entrust the huge amount of information related to products to a practical and flexible support such as the label.

Considering the wide range of possible applications, how can one choose the most suitable labelling machine to integrate into the production and packaging process? Let’s discover the differences and strengths of the Etipack Energy, Strong and Extreme labellers, the very heart of any industrial labelling project.

Width, speed, functions: 3 essential elements to evaluate the most suitable industrial labeller

Among the various elements required to choose the most suitable industrial labelling machine for integration into the production process, here are 3 basic parameters that allow you to quickly identify which labelling machine can meet the requirements of the job in hand:

1. the width of the labels to be applied

2. the speed at which the processing must be carried out

3. considering the electronics, the functions available for managing and controlling the process.

This information, although very synthetic, is, in its simplicity, fundamental to start orienting oneself among the different models and categories of machines available.

Eway labelling machines in comparison: distinctive features of the Strong, Energy and Extreme models

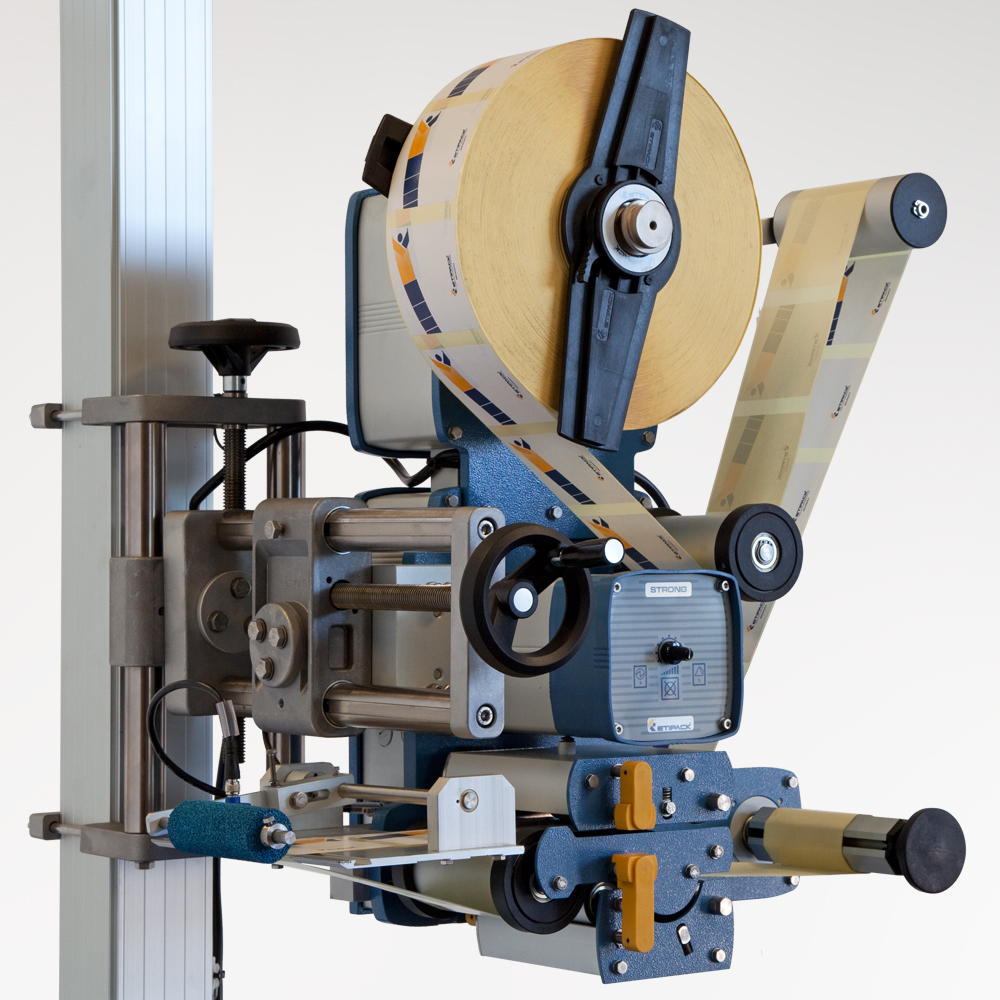

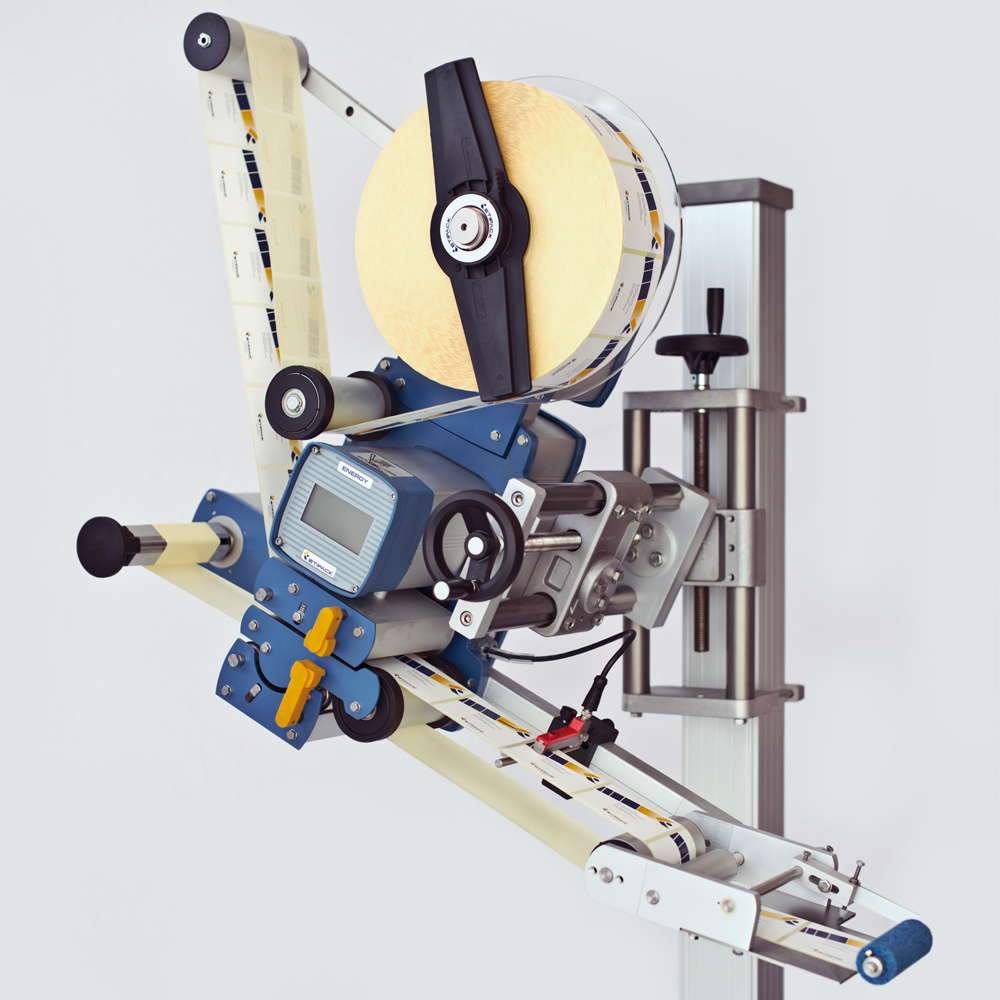

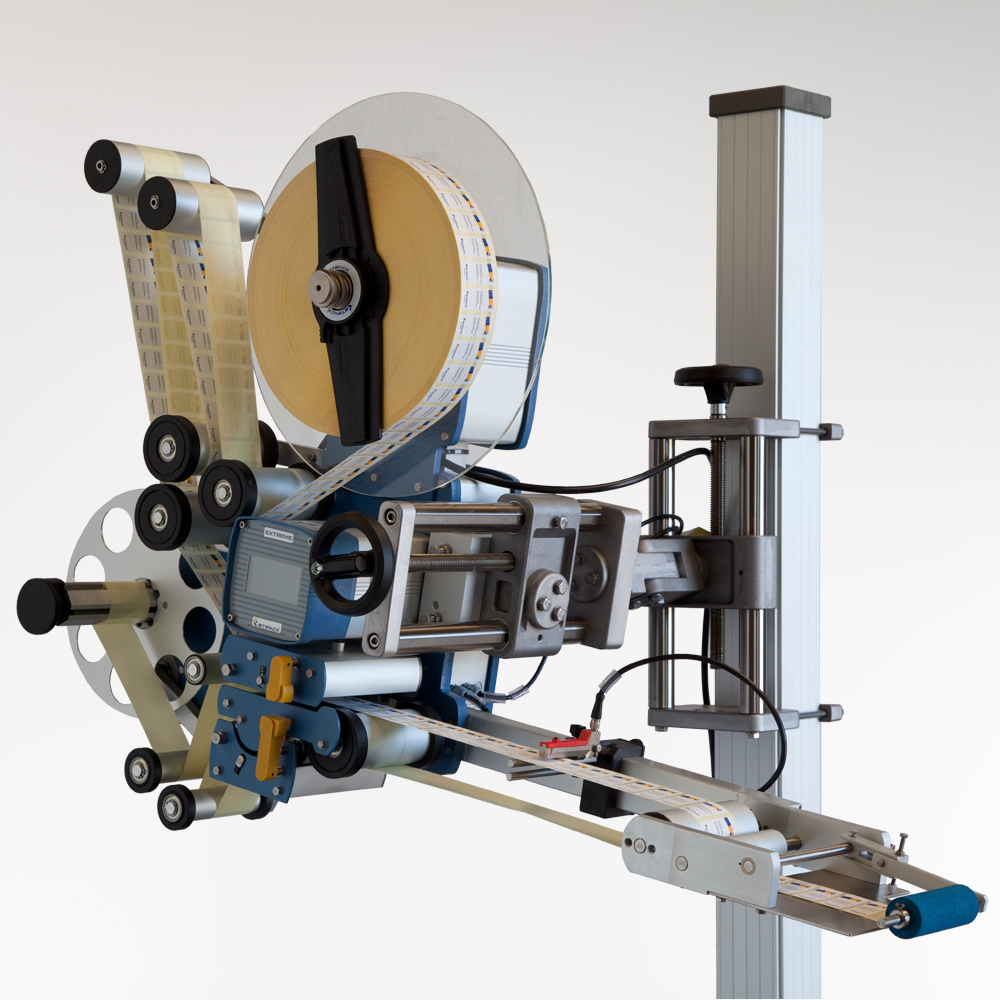

Eway is the innovative generation of Etipack labelling machines, which stand out for their compact design and ease of assembly, allowing quick and simple technical solutions with top performance and reliability. The strength of Eway labellers lies in their modularity: each of the models – Strong, Energy and Extreme – can be adapted to the customer’s production needs thanks to the possibility of modifying or expanding the purchased configuration by integrating additional components. The innovative stepper motor driven by magnetic encoders, ensures maximum labelling precision even at high speeds, and makes it possible to manage several functions at the same time, from motor and speed control to label distribution.

Strong is the most compact labeller in the range. It is available in two different widths, 100 or 200 mm, and can apply labels at a speed of up to 30 meters per minute. Ideal for managing low-complexity processing and low distribution volumes, it is a tough, reliable and affordable entry-level model.

The flagship model of the Eway generation, Energy is the most versatile labeler. Available in three widths: 100, 200 or 300 mm, it applies labels at speeds of up to 60 meters per minute. Thanks to the retrofitted stepper motor, it can reach high application frequencies, always maintaining optimal control over the precision of label distribution. The innovative multi-tasking electronics allows you to manage several functions at the same time, such as the variation of configuration parameters while the machine is running, optimizing working time. The energy-saving function also allows the interruption of power consumption in case of extended inactivity.

Extreme is the highest performing model in the range thanks to its ability to apply labels at speeds of up to 80 meters per minute. Available in three widths – 100, 200 or 300 mm – it inherits and enhances the main features of the Eway generation: retrofitted stepper motor to reach even higher application rates; control of the label distribution precision; management of several functions simultaneously thanks to the innovative multi-tasking electronics and interruption of power consumption in case of protracted inactivity thanks to the energy-saving function.

The configuration of all Etipack labellers can be fully customized by adding applicators and distribution terminals of different lengths according to label application requirements. They also allow the integration of different types of printing units (hot stamping, thermal transfer, inkjet) for printing codes, variable data or images.

Find out more about