Top/bottom labelling of Bfs Strips

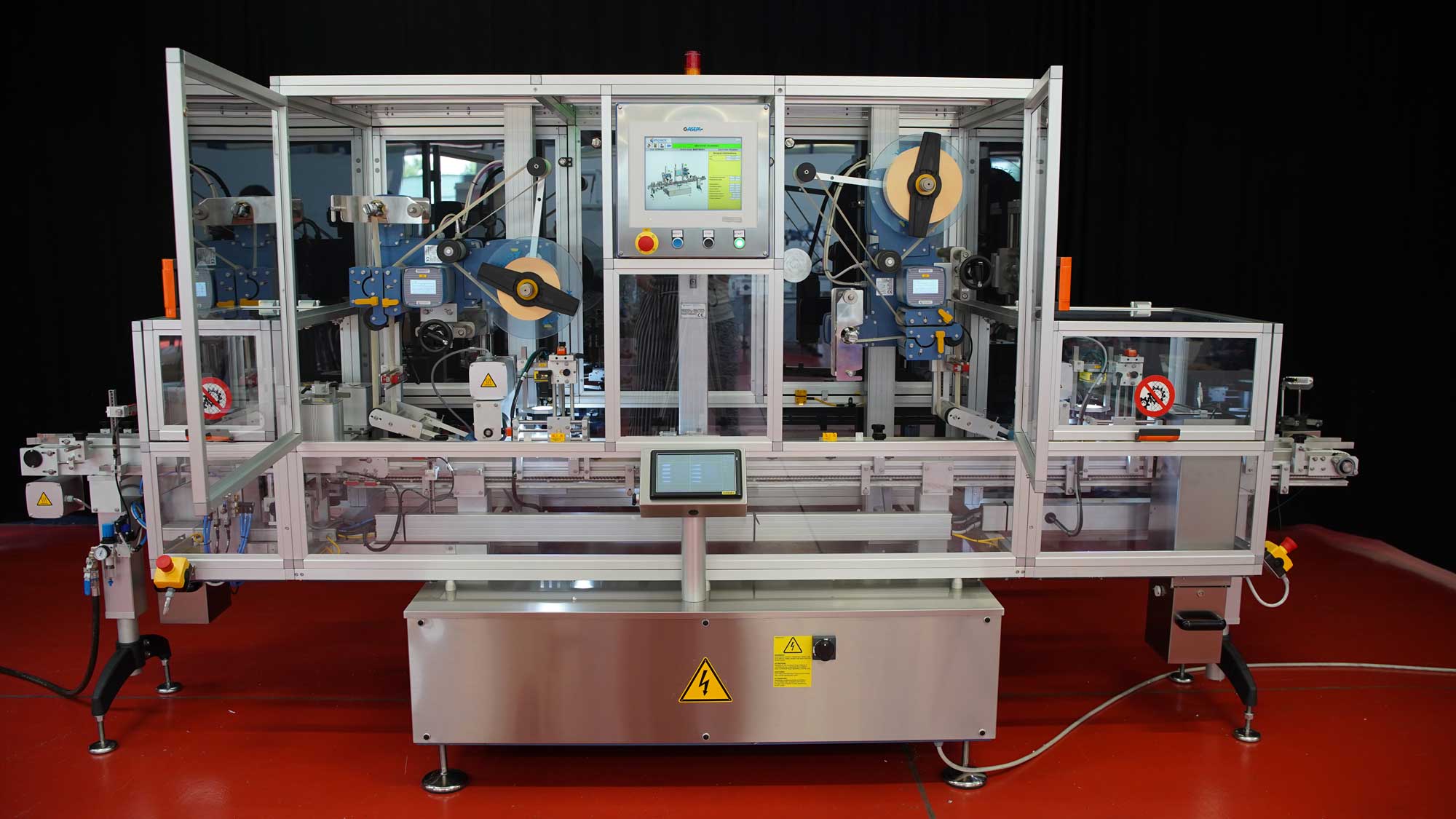

Automatic labelling system to apply multiple pressure-sensitive labels on the top and bottom side of multi-dose Blow Fill Seal strips in the same cycle

The customer, a global pharmaceutical company founded in India, was looking for the right solution to efficiently label multi-dose Blow Fill Seal packages while covering multiple needs. The desired system, in fact, had to apply with precision 5 labels in the upper and lower part of the products; it was required to enable the labeling of both the flaps and the body of the products, as well as simplifying the operator’s activities.

Customized System 2 to perform a top/bottom application of 5 labels on BFS strips, one label for each dose – both on the body and on the tail -, with two labelling stations positioned sequentially on the top of the conveyor belt and to inspect the labels presence.

The System 2 series comprises a range of labelling systems designed for application to the top of products. To meet the requirements of the project, Etipack has designed a special System 2 capable of applying labels to both sides of the product without the need to position a second labelling station under the conveyor belt to carry out the bottom application. The machine can be set to apply the label onto one side – which ever it is – or on both ones. The solution, indeed, incorporates a custom-made device specifically designed to place the product so that it can reach a second labelling station, also located above the belt, which applies the labels on the top side. The designed system is also practical for the operator as it provides greater ease of configuration, facilitates format changes, as well as maintenance and service activities.

System features and configurations

- Rejection system that ejects any overlapping products at the infeed

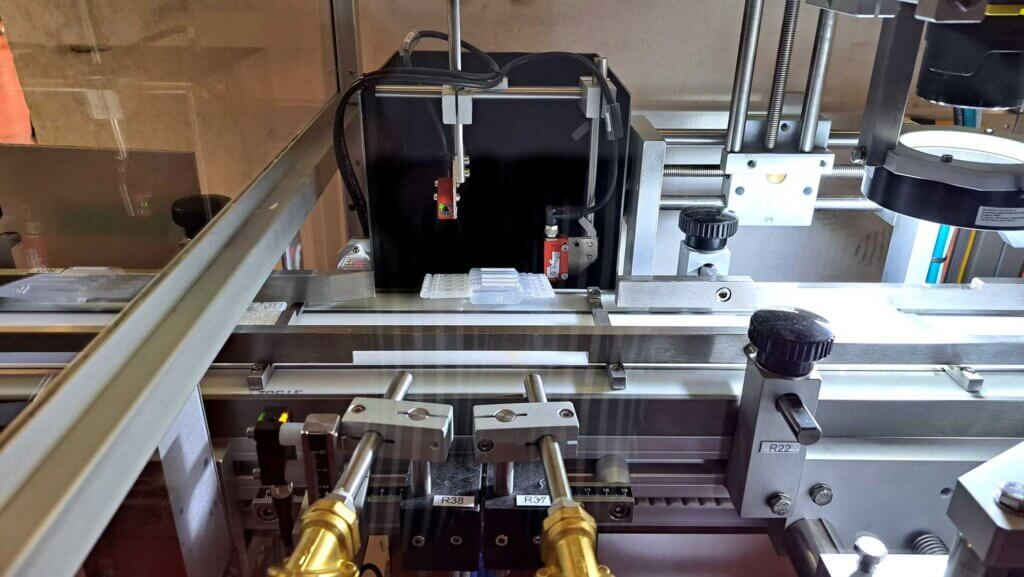

- Customized conveyor system with motorized belts with spacers that accommodate the products while holding them in place.

- 2 Automatic labelling machines ENERGY 100, placed subsequently apply the labels first on the top of the strips, and then on the bottom side with dispensing speed up to 60 m/min.

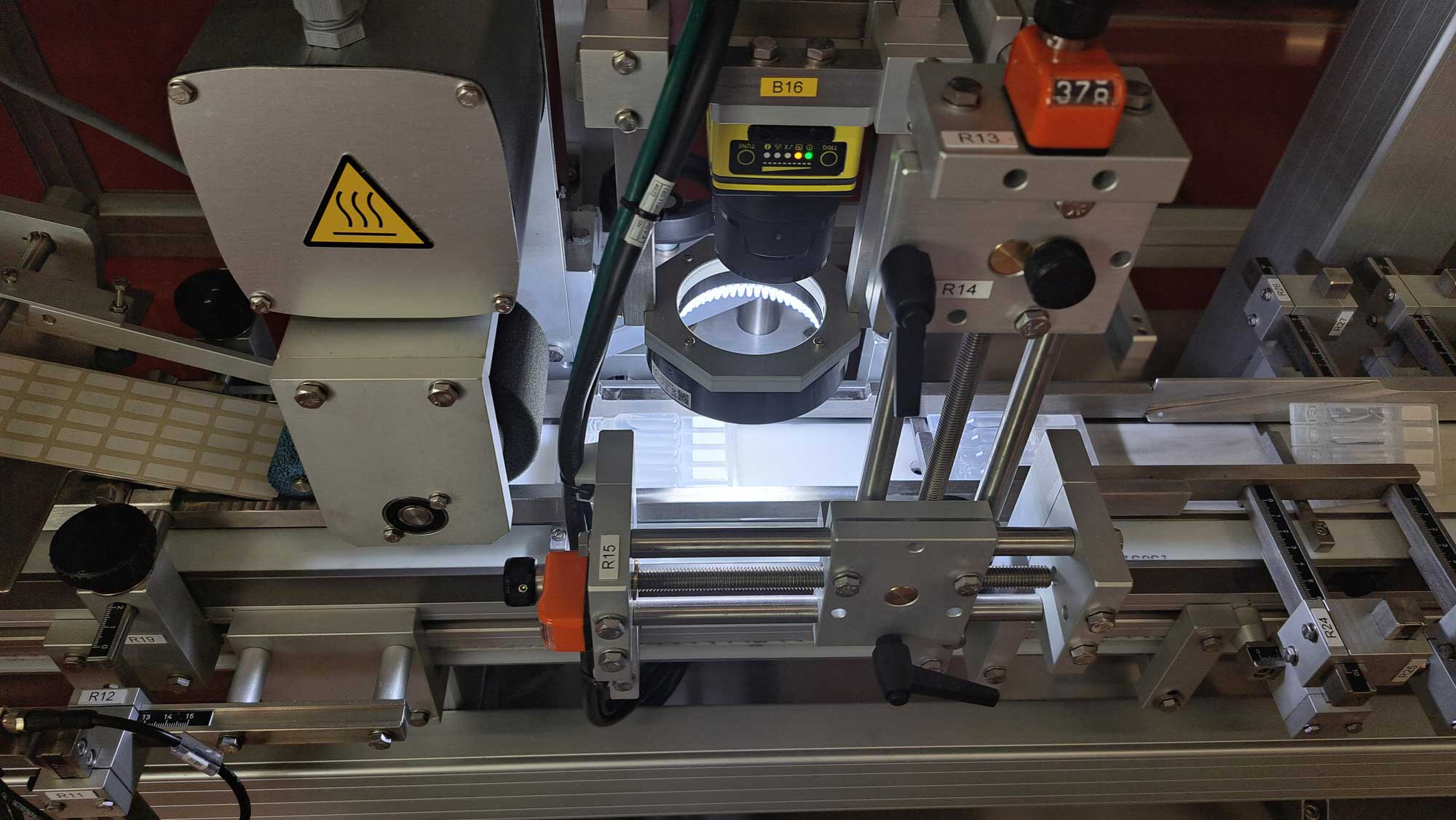

- Plastic media rewinder designed to facilitate the removal of transparent siliconate backing paper

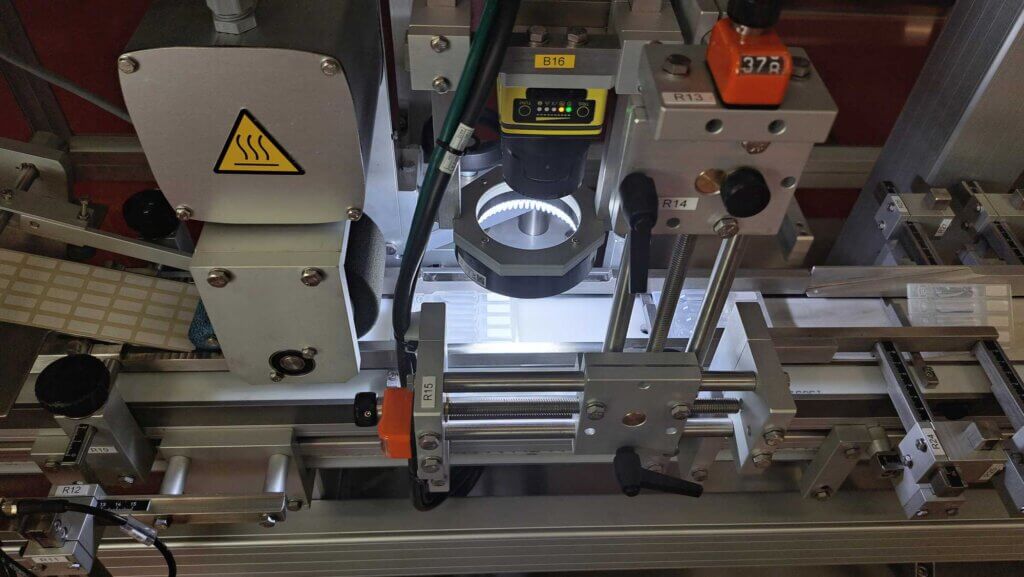

- Cameras with circular illuminator to check products one-by-one and assure that all of them have the 5 labels properly applied where provided.

- Special system for product flipping

- Product check and discard thanks to air ejecting devices and lockable container, with maximum load control device, and rejecting control.

- Control panel with specific pharma features for constant peripheral diagnosis; remote system management and remote assistance; management of FailSafe, back-up/ restore and disaster recovery functions, as well as collection of production batch, CFR21/Audi trail/Alarm and production data reporting.